Product Introduction:

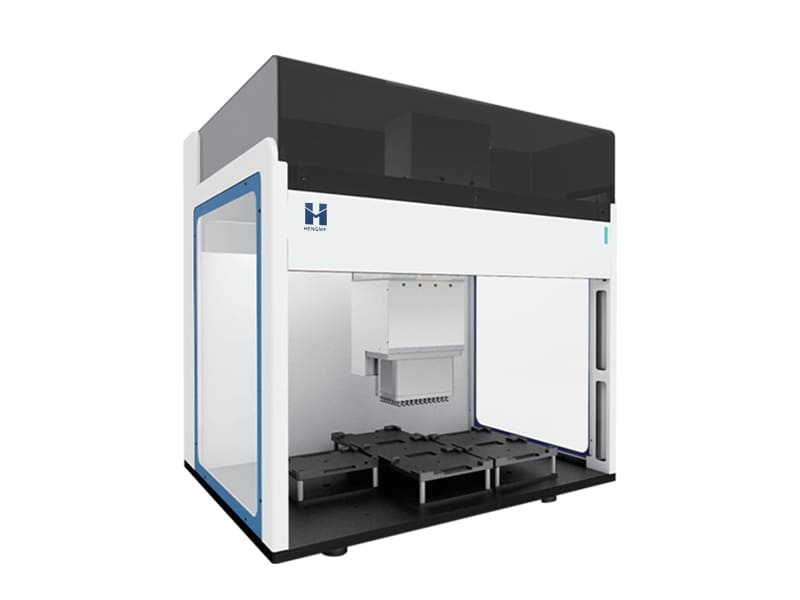

The high-throughput pipetting workstation is a 9-board, 96 pipetting channels, and multifunctional liquid processing platform controlled by self-developed software, with drag and drop programming, simple operation, and user-friendly interface. The working principle of SPARK S09 pipette pump is air displacement pipette, which uses air displacement and a disposable suction head to achieve liquid suction and discharge, avoiding contact between the liquid and the piston and reducing the occurrence of pollution.

The 96 channel pipette head has high precision, stability, flexibility, and pipetting efficiency, and can handle 96, 384, and 1536 well plates in the range of 1-1000 μ Flexible and rapid liquid transfer within a range of l, including single well, single row, single column, multi row, and multi column.

Compact design, space saving, can be placed in biosafety cabinets and ultra clean workstations to avoid sample contamination and protect operators from harmful reagents.

Rich in functions, it can be used alone or integrated into automated laboratories. When used alone, it can be equipped with various modules, such as oscillators, temperature control modules, magnetic racks, temperature control modules, etc

Product features:

Compact design: The exquisite design of 9 boards saves space and can be placed in biosafety cabinets and ultra clean workstations.

Flexible operation: automatic removal and disposal of suction heads; Support single column, multi column, and whole board sampling; Supports gradient dilution in any direction.

Easy programming: can be controlled through wired or wireless, with a brand new touch screen experience, user-friendly software interface, sequential programming, and easy control of instrument operation.

Efficient and precise liquid transfer: using optimized air displacement sealing technology, 96 channel pipette head for efficient liquid transfer; Can accommodate different ranges; Can accurately pipette from 96 or 384 well plates.

Rich in features: supports integration, supports the replacement of multiple ranges of pipettes, supports various temperature controllers, oscillators, and adapters, and can meet different experimental requirements.

Application scenario:

Construction of PCR/qPCR system;

Monoclonal selection;

ELISA;

NGS pre-treatment;

Nucleic acid purification and nucleic acid library screening;

Cell inoculation, planking, and passaging;

96 hole plate to 384 hole plate;

Automated pipetting and separation requirements for experiments such as plate replication, plate format recombination, reagent packaging, compound addition, and column by column or row gradient dilution;

Technical parameters:

Specifications and models: HM-Y9S and HM-Y9H

External dimensions (length x width x height): 635mm x 526mm x 680mm (Y9S: compatible with 96-50, 96-200); 635mm x 526mm x 792mm (Y9H: compatible with three types of pipettes)

Weight: HM-Y9S: 61.5kg HM-Y9H: 70kg

Control system: Surface tablet equipped with SPARK control software

Pipette types: 96-50, 96-200, 96-1000 for optional configuration (supports customized 20ul and 70ul)

Transfer range: 1 μ L-1000 μ L

ANSI/SLAS board positions: 9

Adapted consumables: SBS standard 96/384 well plate, 1.5/2.0ml EP tube

Communication interface: 1 Ethernet port, 1 RS-232 serial port

Power supply conditions: 200-240VAC, 50/60Hz, 6A

Working environment: Temperature: 5-40 ℃ Relative humidity: 10-90% Non condensing

*Suitable working environment: Temperature: 18-22 ℃ Relative humidity: 50% ± 10%

Separation speed: at least 300 plates/h per hour

| Type of pipette head | Transfer volume(μl) | precision | accuracy(±) |

| 50μl | 1 | ≤5% | 0.08 |

| 10 | ≤2% | 0.03 | |

| 200μl | 2 | ≤5% | 0.06 |

| 50 | ≤1% | 0.02 | |

| 1000μl | 100 | ≤0.5% | 0.015 |

| 500 | ≤0.3% | 0.01 |

- Previous: High throughput fully automatic liquid transfer workstation

- Next: no more

Current

Location:

Current

Location: +86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products