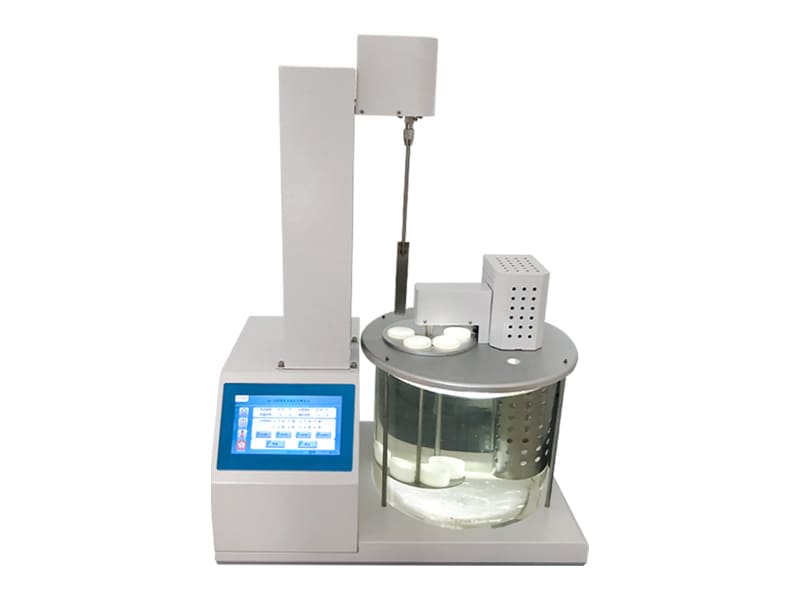

Thank you for selecting LC series automatic distillation range tester, which is designed and manufactured according to GB/T 18255-2000, GB/T 7534-2004 GB/T 314. 1-2010 and GB/T 18589-2001 test methods. It is applicable to the distillation range determination of natural gasoline (stable light hydrocarbon), motor gasoline, aviation gasoline, jet fuel, solvent with special boiling point, naphtha, kerosene, coal tar, diesel, crude diesel distillate fuel and similar petroleum products.

In order to use this instrument correctly, please pay attention to the following items:

Electrical safety: the working power supply of the instrument is 220V AC. Before using the instrument, connect the wires in the power socket of the laboratory, and the instrument shell shall be grounded reliably; When the instrument is out of service, be sure to unplug the power plug.

Risk of fire: During the heating process of the instrument, the distillation bottle may break and cause the leakage of flammable liquid to catch fire. Therefore, when using the instrument, the fire extinguisher must be equipped. During the test, the operator shall keep away from the heating furnace area.

Operation safety: When the instrument is working, it must be guarded by a specially-assigned person to deal with emergencies at any time.

Product features:

The original 10.0-inch 1920x1080 pixel HD LCD is adopted for the display, and the operation interface in Chinese is detailed, intuitive and generous.

Capacitor touch screen is adopted for operation, which has the advantages of no mechanical loss, dust and water proof, radio frequency interference resistance and long service life.

FLASH data memory is used for historical data storage, which can store 10000 historical data.

PT100 platinum resistance temperature sensor with original packaging imported from Germany JUMO Company is used for temperature measurement and control, and matched with high-precision high-speed AD converter, so that the temperature acquisition is faster and more accurate, and it can be easily captured even if the temperature step-type mutation occurs.

Titration monitoring system adopts modern advanced infrared optical detection technology, cooperates with high-precision photoelectric sensor, accurately captures every drop of sample, and automatically tracks the liquid level with high accuracy.

Semiconductor refrigeration technology is adopted to automatically control the temperature of condenser tube and recovery room.

Use high-precision temperature sensor to * * measure steam temperature.

The instrument realizes automatic control of electric furnace power, automatic tracking of liquid level, automatic control of temperature and automatic calculation of recovery chamber and condenser tube.

Built-in thermal printer for automatic printing of test results.

Constant temperature range of condensation bath: 0-60 ℃.

Temperature sensor: German Class A Pt 100.

Volume detection range: 0-100mL, resolution: 0.01mL.

Steam temperature measurement range: 0-400 ℃, resolution: 0.1 ℃.

Constant temperature range of recovery chamber: 0-50 ℃, temperature control accuracy ± 1 ℃.

Measured value display resolution: 0.1 ℃ and 0.1% recovery.

Temperature control range of heating furnace: room temperature - 500 ℃.

Condenser tube temperature control range: - 20-70 ℃, temperature control accuracy ± 1 ℃.

Distillation bottle specification: 125ml, measuring cylinder specification: 100ml

Power supply: AC220V 50Hz * high power less than 2500W

Service environment temperature: 10-40 ℃

Storage environment temperature: 0 ~ 50 ℃

Ending mode of the experiment:

1. Dry point end: end the test when dry point is detected.

2. End of final distillation point: end the experiment when the final distillation point is detected and print out.

3. End of temperature: end the experiment according to the temperature value set by the user and print out;

4. End of volume: end the experiment according to the volume value set by the user and print out;

- Previous: no more

- Next: no more

Current

Location:

Current

Location: +86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products