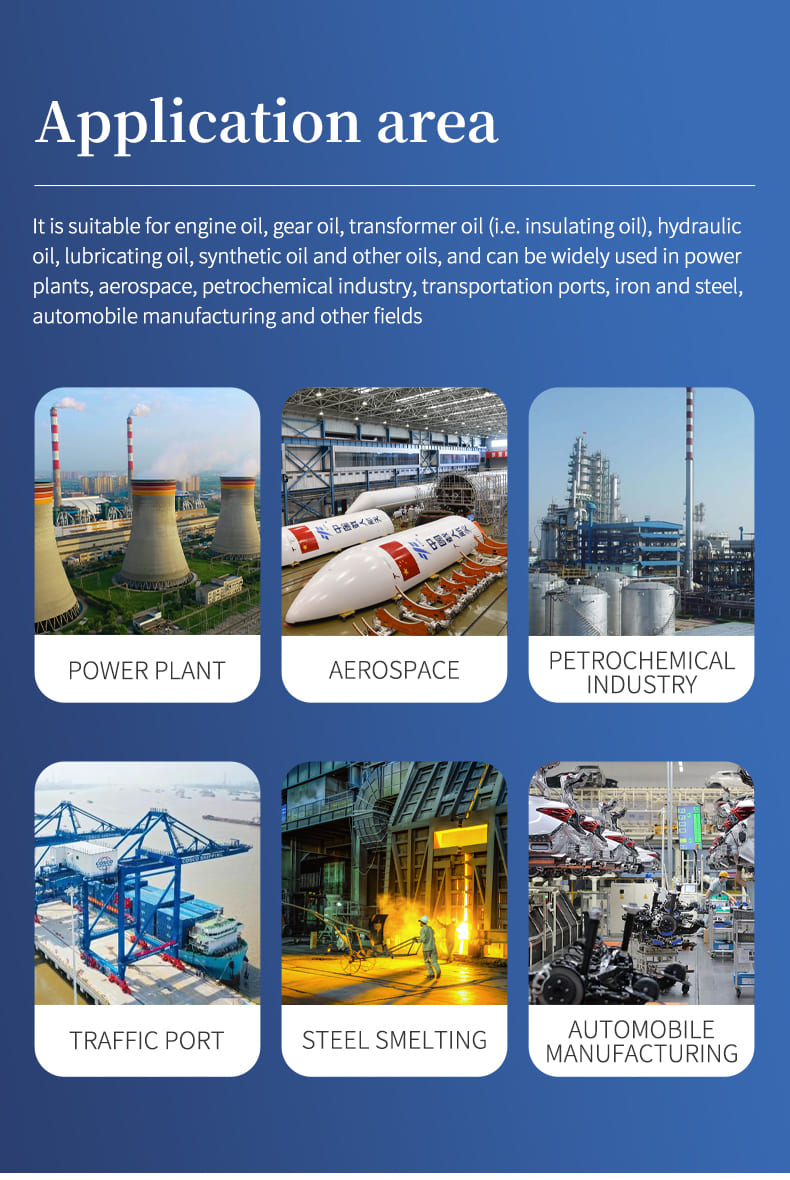

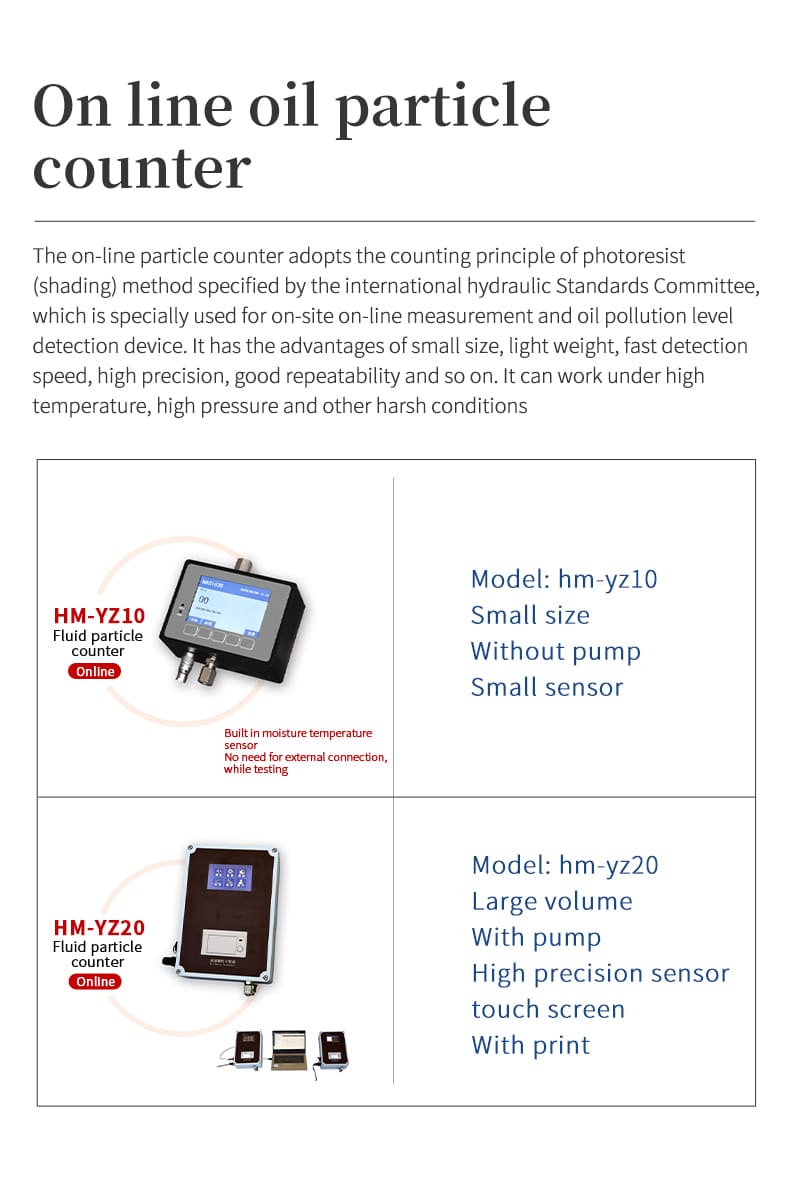

The HM-YZ20 online oil contamination detection instrument is a device specifically designed for detecting the level of pollution particles in liquids, using the counting principle of the light blocking (shading) method specified by the International Hydraulic Standards Committee and based on national and international standards such as GB/T 18854-2002 (ISO11171-1999). Can provide fast, accurate, reliable, and reproducible detection results. Easy and convenient to operate, suitable for online monitoring of various oil systems. Two (or more) slave machines can also be connected to the same host or platform for comparative testing, with simple operation and flexible combination. It can be widely used in aviation, aerospace, power, petroleum, chemical, transportation, ports, metallurgy, water treatment, machinery, automobile manufacturing and other fields.

Performance characteristics:

Using the counting principle of the optical obstruction (shading) method specified by the International Hydraulic Standards Committee

High precision laser sensor with wide testing range, stable performance, low noise, and high resolution

Adopting high-precision dual plunger pump, stable injection speed, and high sampling accuracy

Can be equipped with a built-in pressure reducing device for online high-pressure testing

Built in GJB-420A, GJB-420B, SAE4059E, ISO4406, GB/T14039, NAS1638, and Г Common standards such as OST17216 support custom standard testing and can be set according to customer needs

Equipped with a built-in data analysis system, it can automatically determine the sample level according to standards, continuously monitor the hydraulic system, and have an alarm function

Built in multiple calibration curves, compatible with all commonly used domestic and international standards for calibration

Can achieve continuous and automatic online detection, and can set the detection interval time arbitrarily

Equipped with RS232, RS485, and USB interfaces, it can be connected to computers or laboratory platforms, as well as industrial fieldbus

With data storage and printing functions, it is convenient for data organization and archiving

Can be used alone, can be used online upstream and downstream to calculate filtration rate, can be monitored by multiple interconnected remote upper computers, can generate curve graphs, historical queries, data exports, etc., with diverse combinations and strong scalability in application scenarios

Can control instrument functions and external dimensions according to customer needs

High strength metal shell, suitable for use in harsh environments such as on-site environments

Product technical indicators

Light source: semiconductor laser

Particle size range: 0.8 µ m to 500 µ m (depending on the selected sensor)

Sensitivity: 1 μ M (ISO4402) or 4 μ M (c)

Sampling volume: 0.2-1000ml (fixed at 10)

Sampling volume accuracy: better than ± 1%

Detection speed: 20mL/min or set according to customer needs

Limit overlap error: 40000 particles/mL

Repeatability: RSD<2%

Resolution: better than 10%

Count accuracy: better than 10% (less than ± 0.1 pollution levels)

Online pressure detection: 0.1~0.6Mpa (optional pressure reducing device * high pressure can reach 40MPa)

Online detection interval: 1 second to 23 hours, 59 minutes, and 59 seconds

Detection channel: 8 channels with arbitrary particle size settings

Protection level: IP56

Test sample temperature: 0 ℃~80 ℃

Working temperature: -20 ℃~60 ℃

Power supply: 100-240VAC or DC24V

- Previous: Online oil particle counter

- Next: Liquid particle counter

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products