Product Introduction:

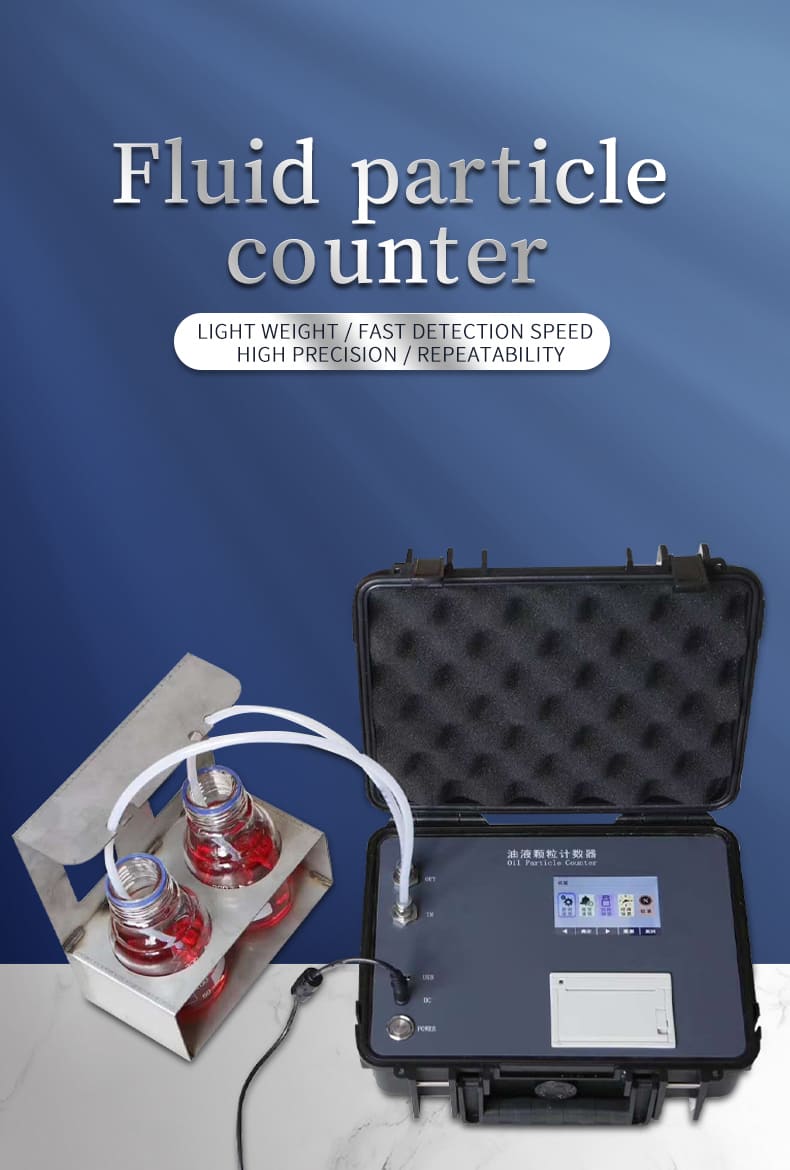

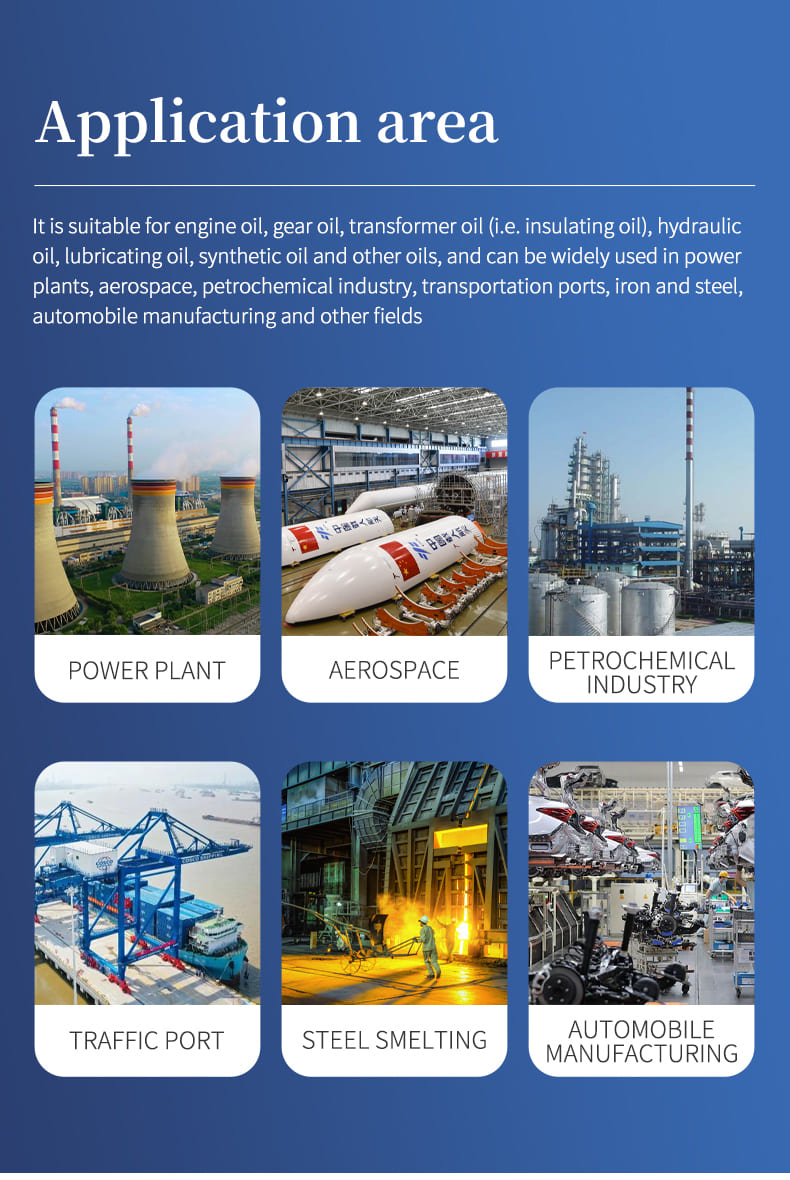

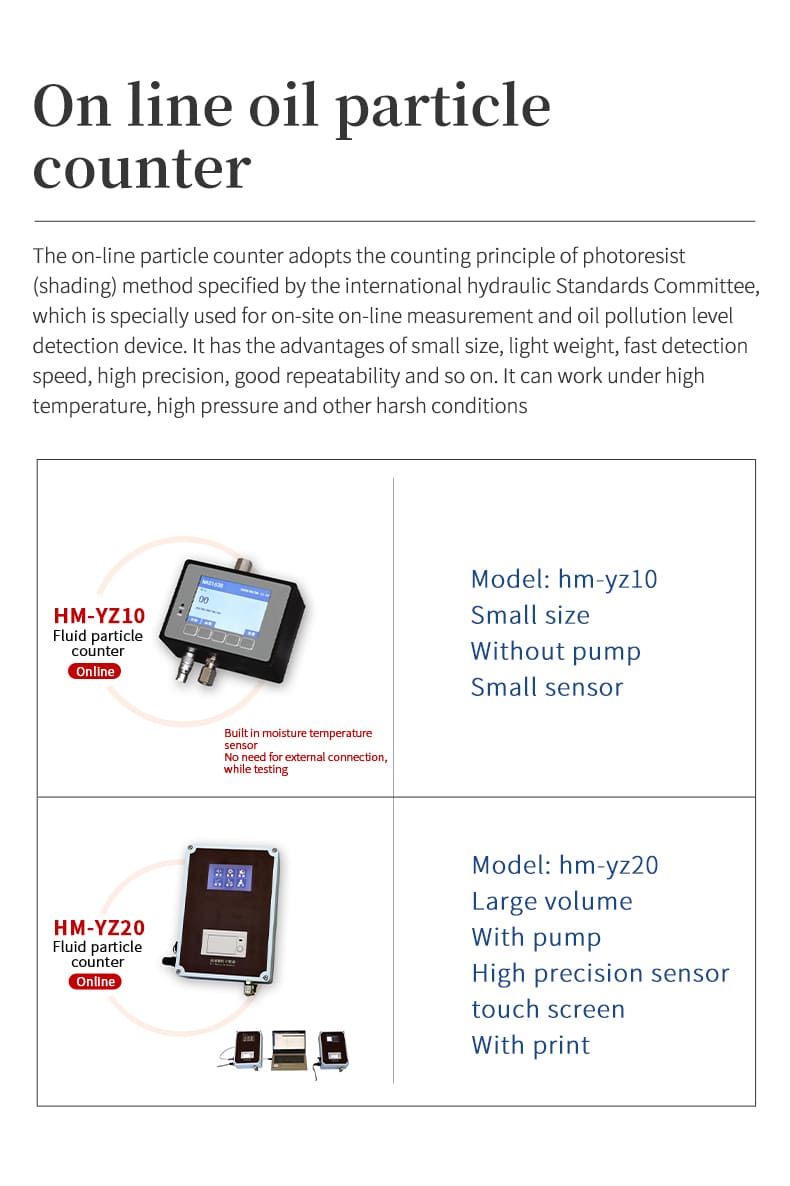

The HM-Y20 portable oil particle counter is an upgraded version of P5, which adopts the light blocking (shading) counting principle specified by the International Hydraulic Standards Committee. It is specifically designed for rapid detection and analysis of oil particle size, cleanliness, and pollution levels on site. It has the advantages of small size, light weight, fast detection speed, high accuracy, and good repeatability, and can work under harsh conditions such as high temperature and pressure. Equipped with a built-in micro water sensor and temperature sensor, it can detect both water content and oil temperature during pollution detection. Suitable for transformer oil (i.e. insulation oil), hydraulic oil, lubricating oil, synthetic oil and other fluids, it can be widely used in fields such as power plants, aerospace, petrochemicals, transportation and ports, steel metallurgy, and automotive manufacturing.

Main features:

Adopting the principle of light obstruction (shading) and using high-precision laser sensors, it has a small volume, high accuracy, and stable performance

Suitable for laboratory or on-site testing, and can also be equipped with a pressure reducing device for online high-pressure measurement, real-time monitoring of particle contamination in the oil system

Can be externally connected to a pressure chamber to form positive/negative pressure, achieving the detection of high viscosity samples and sample degassing

Built in data analysis system that can display real data on particle size of each channel and automatically determine sample grade

The pipeline is made of 316L and PTFE materials, which meet the testing requirements for various organic solvents and oil products

Equipped with volume flushing and duration flushing modes, convenient for users to use and maintain the equipment

Built in ISO4406, NAS1638, SAE4059 (integral and differential), GJB420A, GJB420B Г Particle pollution level standards such as OCT17216 and GB/T14039

Built in calibration function, can be calibrated according to standards such as GB/T21540, ISO4402, GB/T18854, etc

Built in data analysis system, capable of automatically determining sample grade based on standards, with automatic data processing and printing functions

Built in micro water sensor and temperature sensor

Bilingual Chinese and English, one click switch, with preset, input, modification, and storage functions, convenient and fast operation

Large storage capacity, can be selected to be stored inside the instrument or on external storage devices

Embedded design, high-strength shell, easy to carry, suitable for various construction machinery

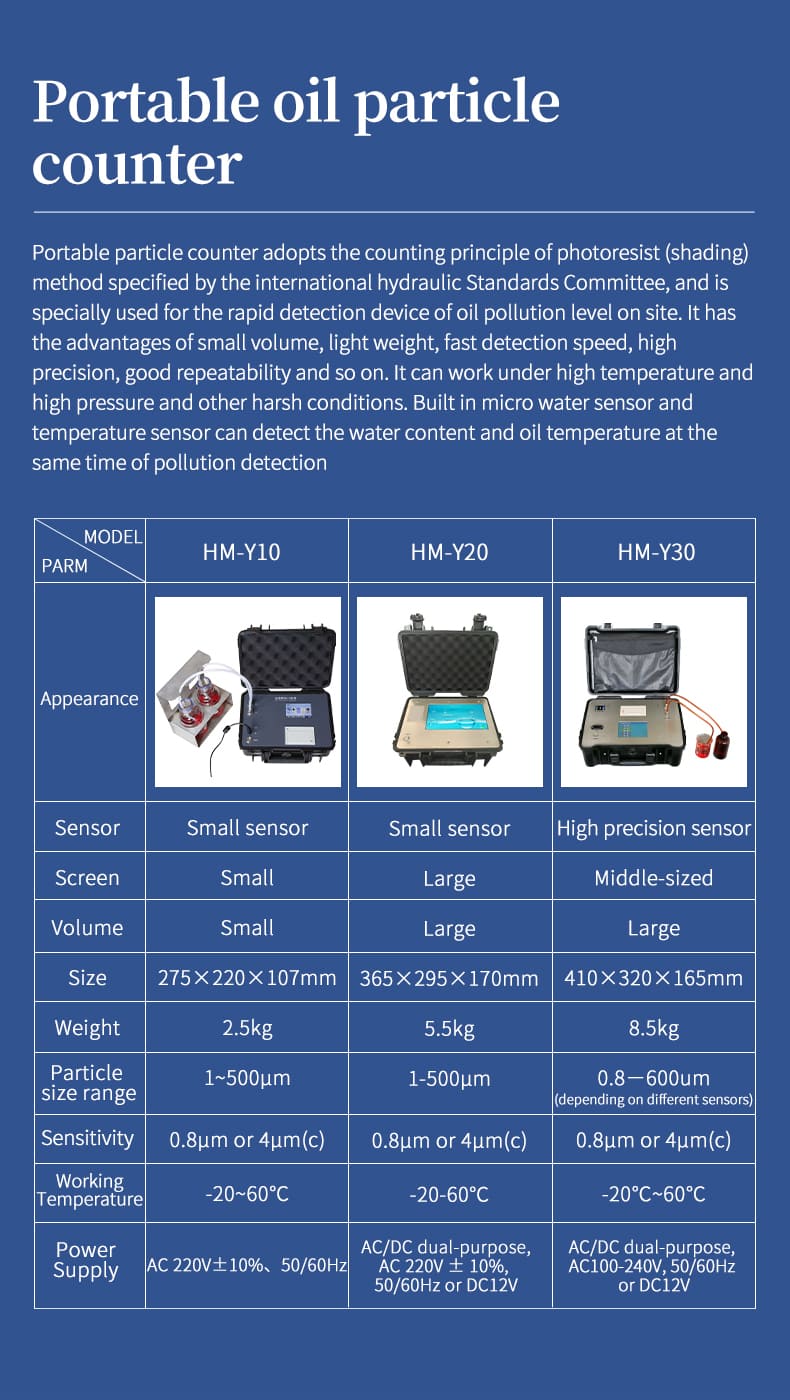

Technical indicators:

Light source: semiconductor laser

Offline detection speed: 5-60mL/min

Offline testing of sample viscosity: ≤ 100cSt (pressure chamber can be optionally equipped when viscosity is high)

Online pressure detection: 0.1-0.6Mpa (optional pressure reducing device * high pressure can reach 42Mpa)

Particle size range: 1-500 μ M

Interface: USB interface, power interface

Data storage: Provides 1000 sets of data storage space and supports USB storage

Sensitivity: 0.8 μ M or 4 μ M (c),

(1) Adopting the ISO4402 AC standard; Measurement range: 1 μ M-100 μ m. Sensitivity 0.8 micrometers

(2) Adopting the ISO11171 MTD standard; Measurement range 4 μ M-70 μ M (C) Sensitivity 4 microns

Limit overlap error: 40000 particles/ml

Counting volume: 1-999ml

Counting accuracy: error less than ± 10%

Protection level: IP67

Test interval: 1 second to 24 hours

Test sample temperature: 0-80 ℃

Reference value for water activity: 0-1aw (± 0.05aw)

Water content: 0-360ppm (± 10%)

Working temperature: -20-60 ℃

Power supply: AC/DC dual-purpose, AC 220V ± 10%, 50/60Hz or DC12V

Weight: 5.5kg

Screen size: 10.2 inches

Battery capacity: 8000mAh

Volume: 365 x 295 x 170mm

- Previous: Oil cleanliness tester

- Next: Oil particle counter

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products