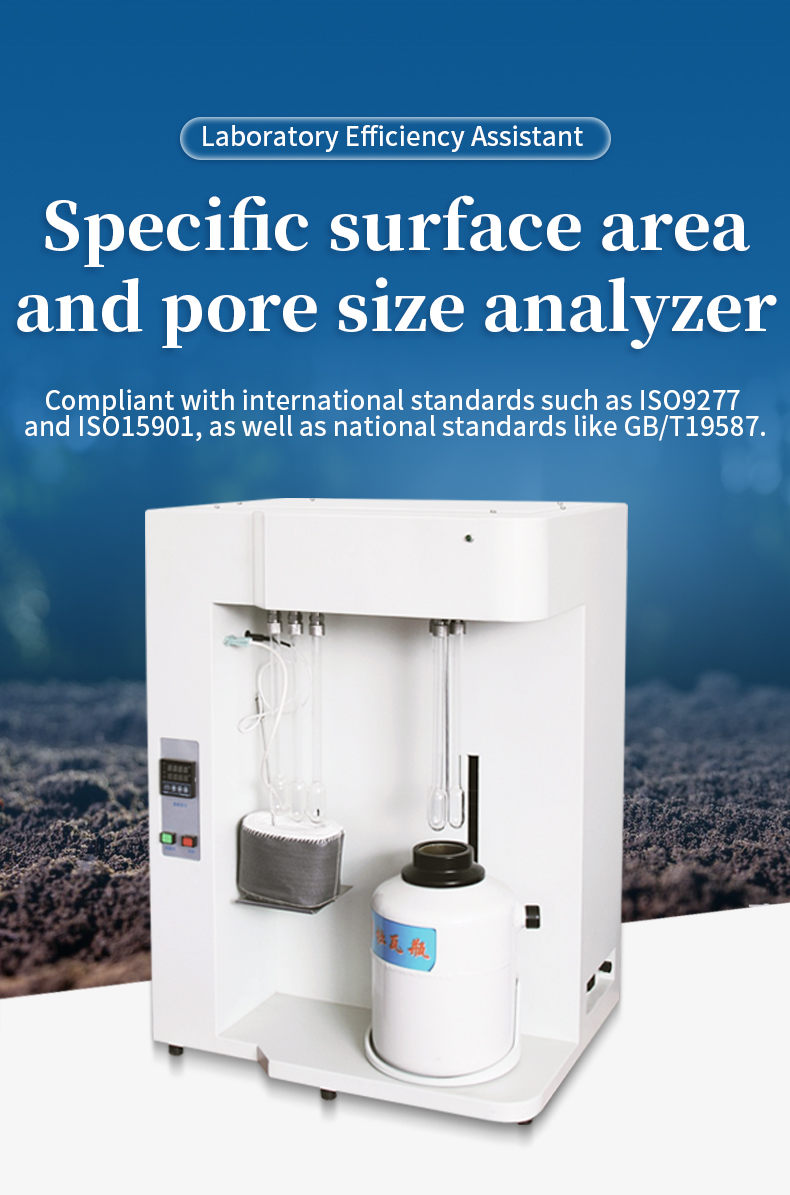

Instrument Introduction:

The fully automatic specific surface area and porosity analyzer complies with international standards such as ISO9277, ISO15901, and national standards such as GB/T19587. The adsorption process is tested using the static capacity method through mass balance equations, static gas equilibrium, and pressure measurements. The testing process is conducted at liquid nitrogen temperature. When a known amount of gas is injected into the sample tube through a branch, it will cause a pressure drop. Therefore, the molar mass of the adsorbed gas at adsorption equilibrium can be calculated. By measuring the equilibrium adsorption capacity, the theoretical model is used to determine the single point and multi-point BET specific surface area and Langmuir specific surface area of the tested sample; Volume and area distribution of BJH mesopores and macropores, total pore volume; T-plot micropore volume and surface area, Dubinin Astakhov micropore distribution, Horvath Kawazoe, SF micropore distribution, MP micropore distribution; Non local density function theory (NLDFT) and Monte Carlo (GCMC) aperture distribution model parameters.

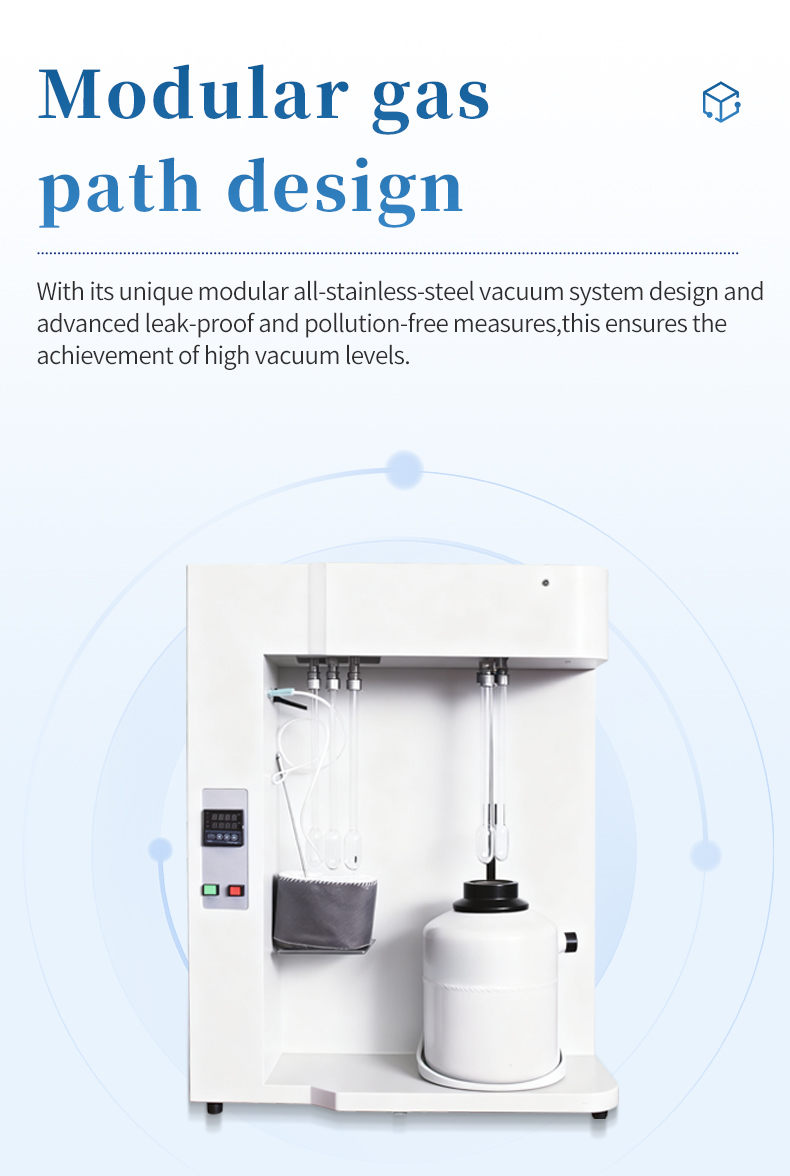

◆ Modular air circuit design

The fully automatic surface area and porosity analyzer introduces advanced design concepts, adopts a unique modular all stainless steel vacuum gas path design and advanced leak proof and pollution-free measures, thereby ensuring the realization of high vacuum and avoiding the disadvantages of easy leakage due to too many connecting pipeline joints.

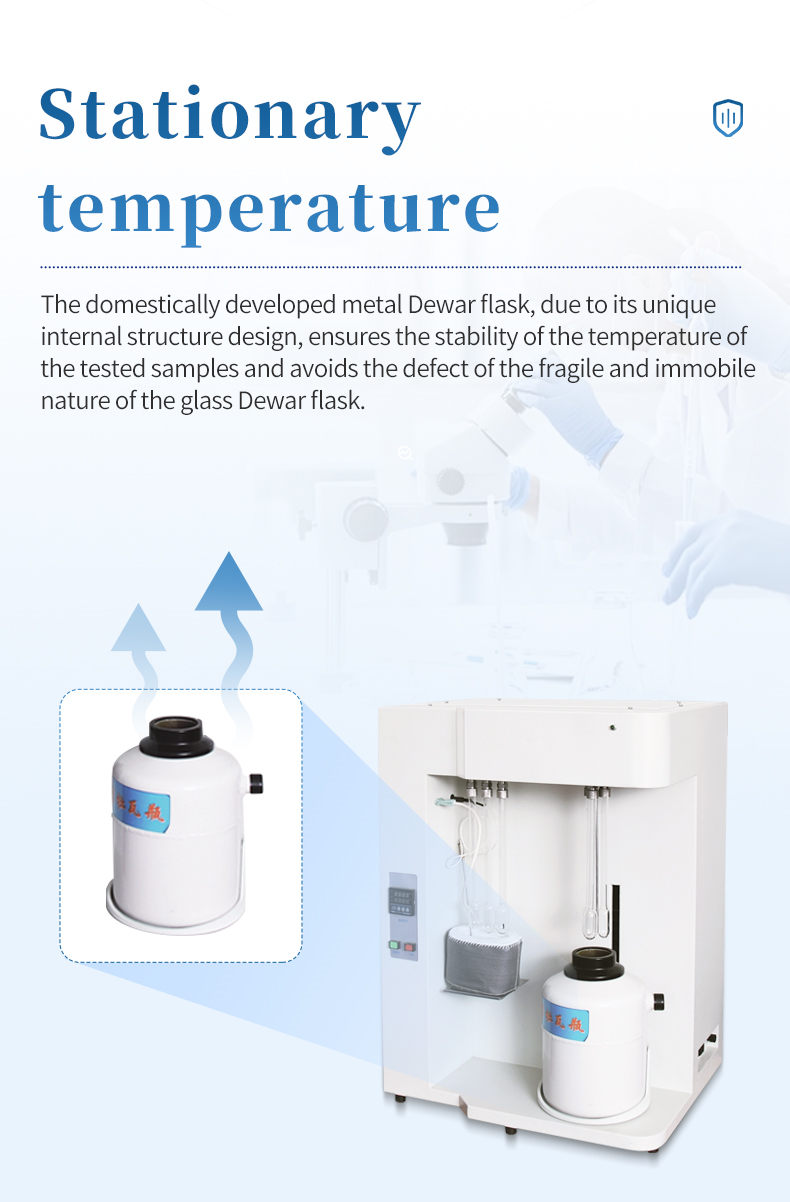

◆ Constant temperature

The independently developed metal Dewar flask, due to its unique internal structural design, ensures a constant temperature of the tested sample while avoiding the fragility and inability to move of glass Dewar flasks.

◆ High precision sensors

Multiple high-precision sensors and 22 bit AD conversion devices ensure the accuracy of specific surface area and aperture calculations.

Advanced theoretical models

Its advanced density function theory (NLDFT) and Monte Carlo (GCMC) pore size distribution model have established its dominant position in China's specific surface area and porosity analyzer industry, and it is also at a leading level internationally.

◆ Operational automation

The adsorption and desorption processes are all computer-controlled and do not require manual operation

Technical features:

Single point and multi-point BET specific surface area, Langmuir specific surface area

BJH mesopore, macropore volume, area distribution, total pore volume

T-plot micropore volume and surface area

Dubinin Astakhov micropore distribution

Horvath Kawazoe, SF micropore distribution

MP micropore distribution

Density Function Theory (NLDFT) and Monte Carlo (GCMC) Aperture Distribution Model

True density test

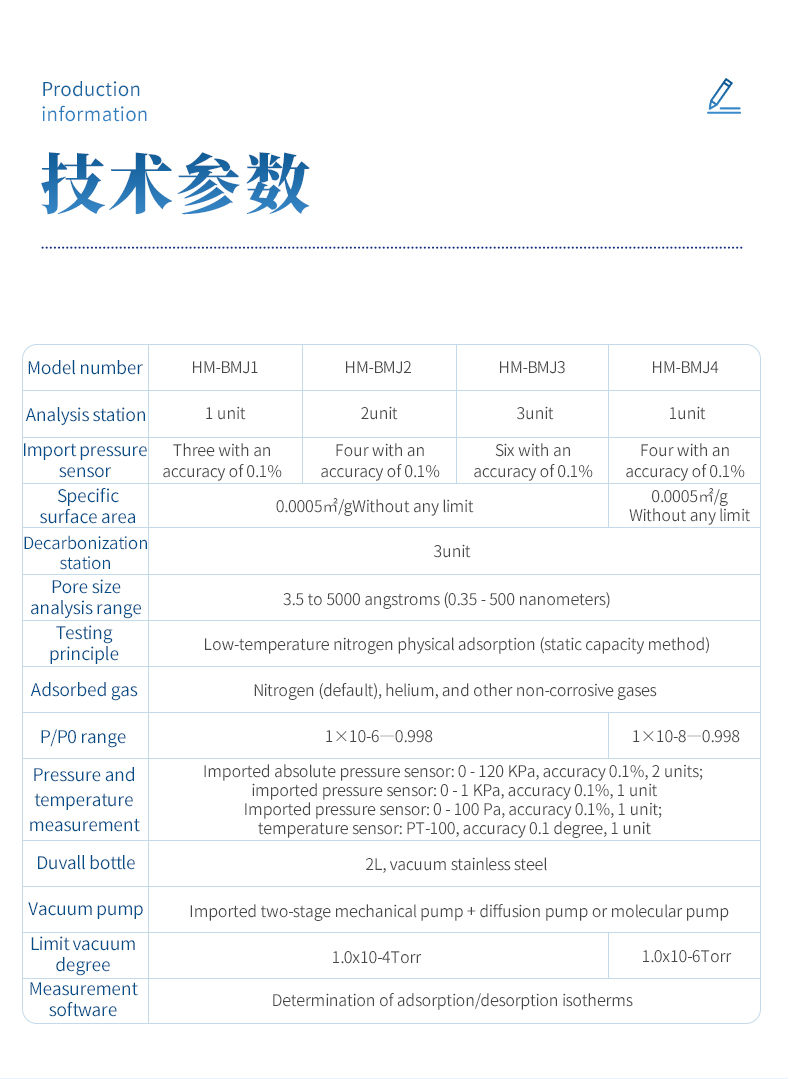

Technical parameters:

1. Specific surface area: 0.0005 ㎡/g to no upper limit

2. Aperture analysis range: 3.5 to 5000 angstroms

3. Test principle: Low temperature nitrogen physical adsorption (static capacity method)

4. Adsorbed gases: Non corrosive gases such as nitrogen (default) and helium.

5. Independent P0 saturation pressure test tube, P/P0 range 1 × 10-6-0.998

6. Pressure and temperature measurement:

Imported absolute pressure sensor 0-133KPa, accuracy 0.12%, 6 pieces.

Temperature sensor: PT-100, accuracy 0.1 ℃ 1 piece

7. Dewar flask: 2L, vacuum stainless steel.

8. Vacuum pump: imported two-stage mechanical pump

9. Ultimate vacuum degree: 1.0x10-4 Torr

10. Measurement software: determination of adsorption/desorption isotherms

11. There are 3 analysis stations and 3 degassing stations, with a degassing temperature of up to 400 ° C. The analysis stations are immersed in a Dewar flask for simultaneous analysis, ensuring minimal dead volume and improving analysis accuracy. Three degassing positions are located in the same soft heating package, and the analysis position is not used as a degassing position.

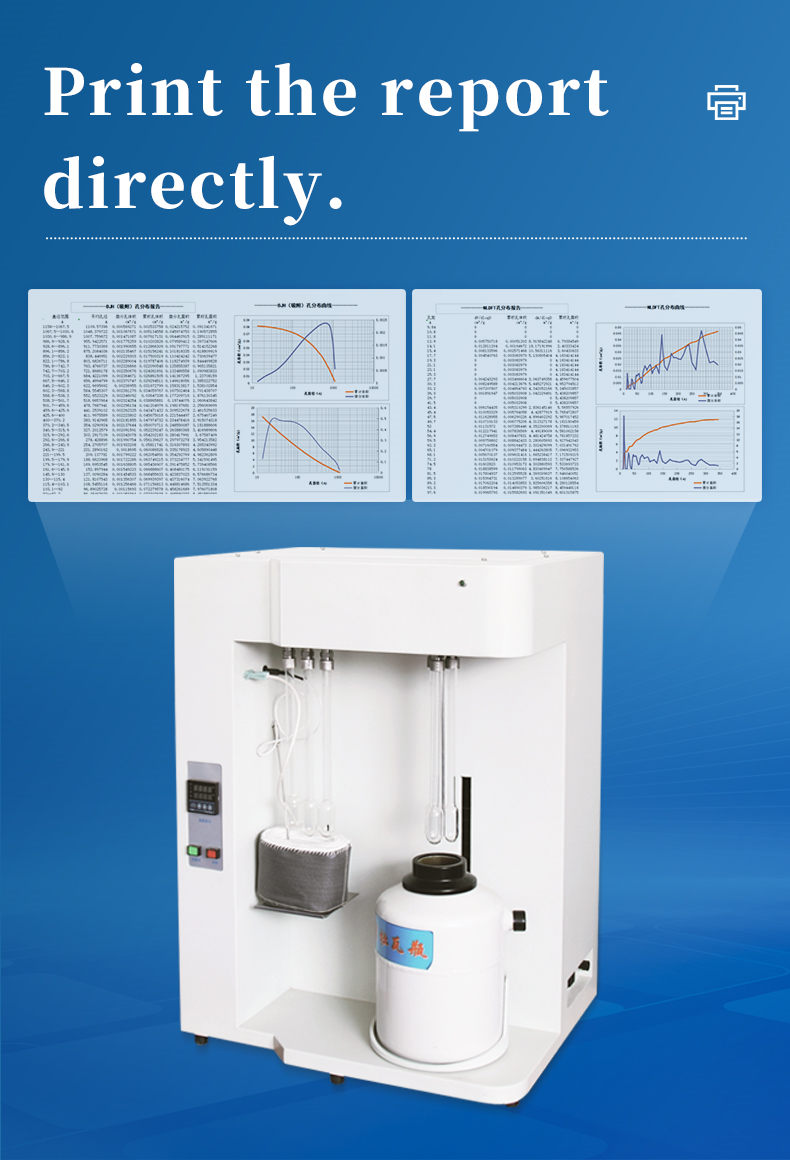

Output report:

Directly print and EXCEL output adsorption desorption isotherms, BET specific surface area, Langmuir specific surface area, t-plot micropore volume, BJH pore volume, pore area, total pore volume, total pore area, Dbinin Astakhov, Horvath Kawazoe micropore distribution, NLDFT/GCMC pore distribution, and review report.

Application scope:

Research and product testing of various materials, including measuring zeolites, molecular sieves, silica, alumina, soil, clay, catalysts, organic metal compound skeleton structures, and other materials.

Address of this article:https://www.kjhm.net/bmj/816.html

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products