Product Introduction

Microwave Digester is a device used for sample pretreatment, which rapidly and effectively digests samples through microwave heating technology. This instrument is widely used in fields such as food, environmental protection, disease control, quality supervision, commodity inspection, research institutes, etc. It is particularly suitable for acid digestion and solvent extraction of various samples.

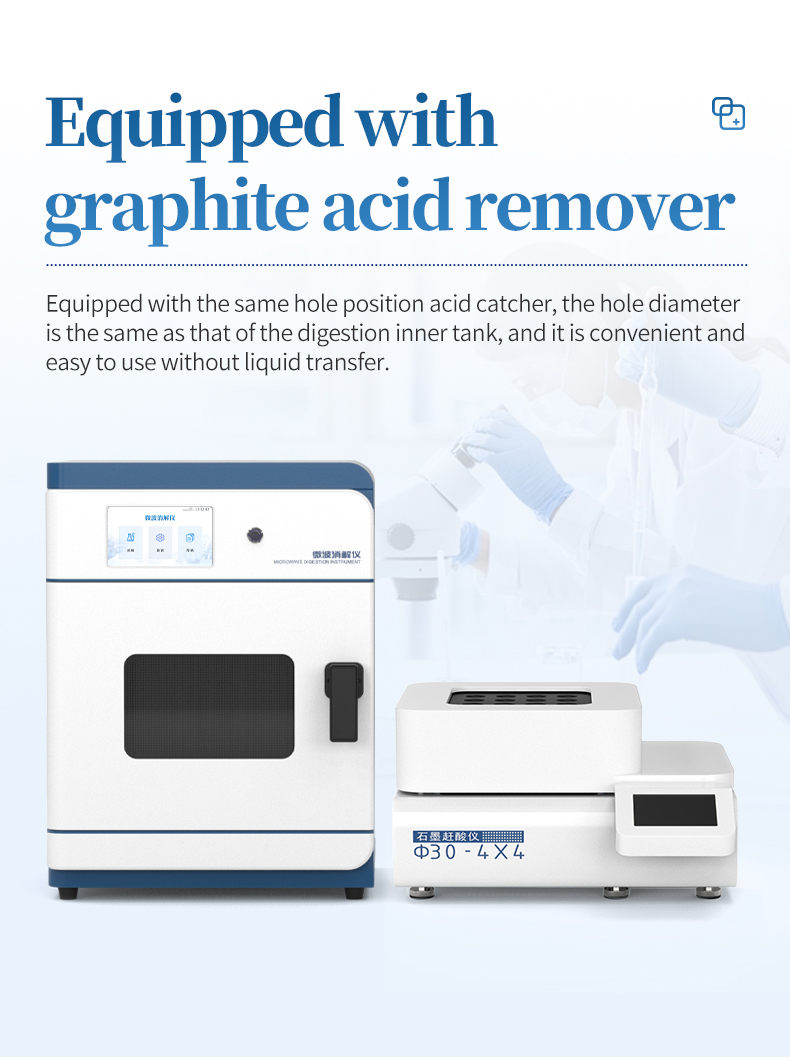

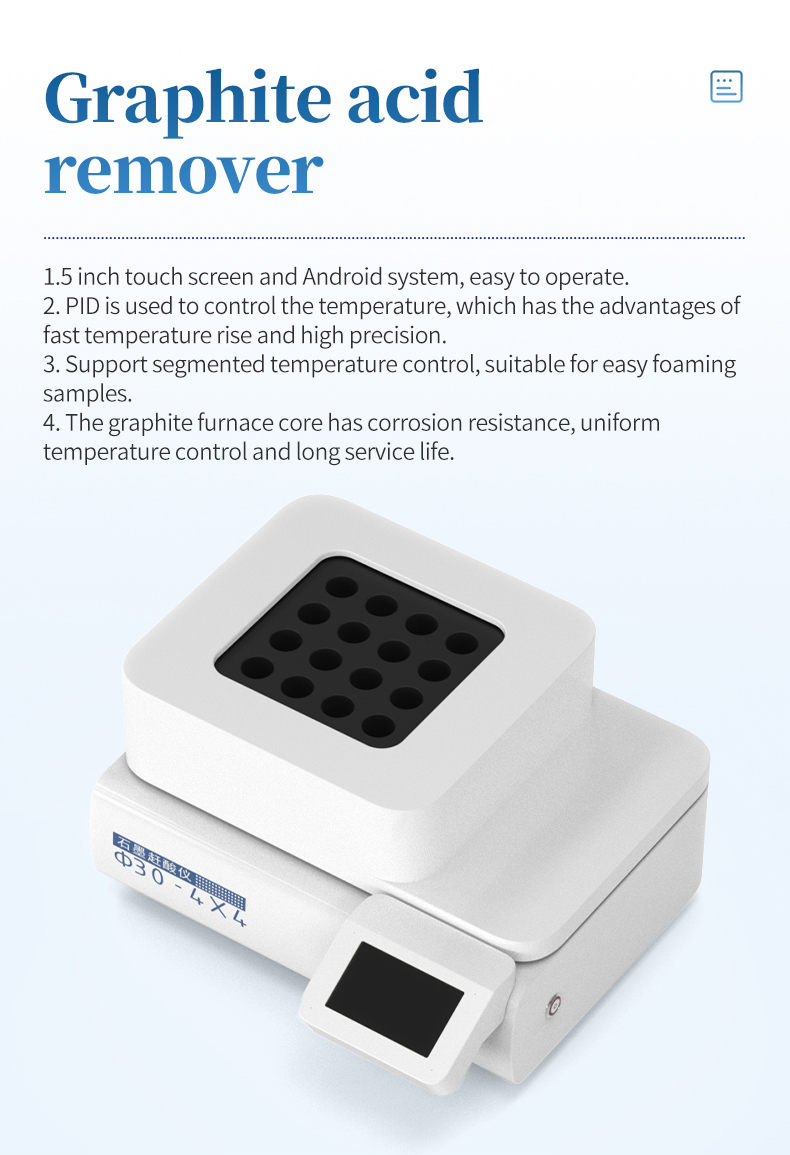

Equipped with an acid analyzer with the same pore size as the digestion inner tank, it is convenient and easy to use without the need for liquid transfer.

Working Principle

The microwave digester rapidly decomposes the sample under high temperature and high pressure through the direct heating effect of microwave electromagnetic waves. The heating principle is mainly achieved through molecular and ion conduction effects:

Molecular effect: Polar molecules collide and rub at high speeds in a microwave electric field, forming high heat.

Ionic conductivity effect: Ions in a solution flow directionally under a microwave electric field, generating high-speed friction and collision, converting microwave energy into thermal energy.

The advantages of microwave digestion technology include fast and complete sample decomposition, low loss of volatile elements, low reagent consumption, simple operation, high processing efficiency, low pollution, and low blank. It is known as the "green chemical reaction technology".

Technical Specifications:

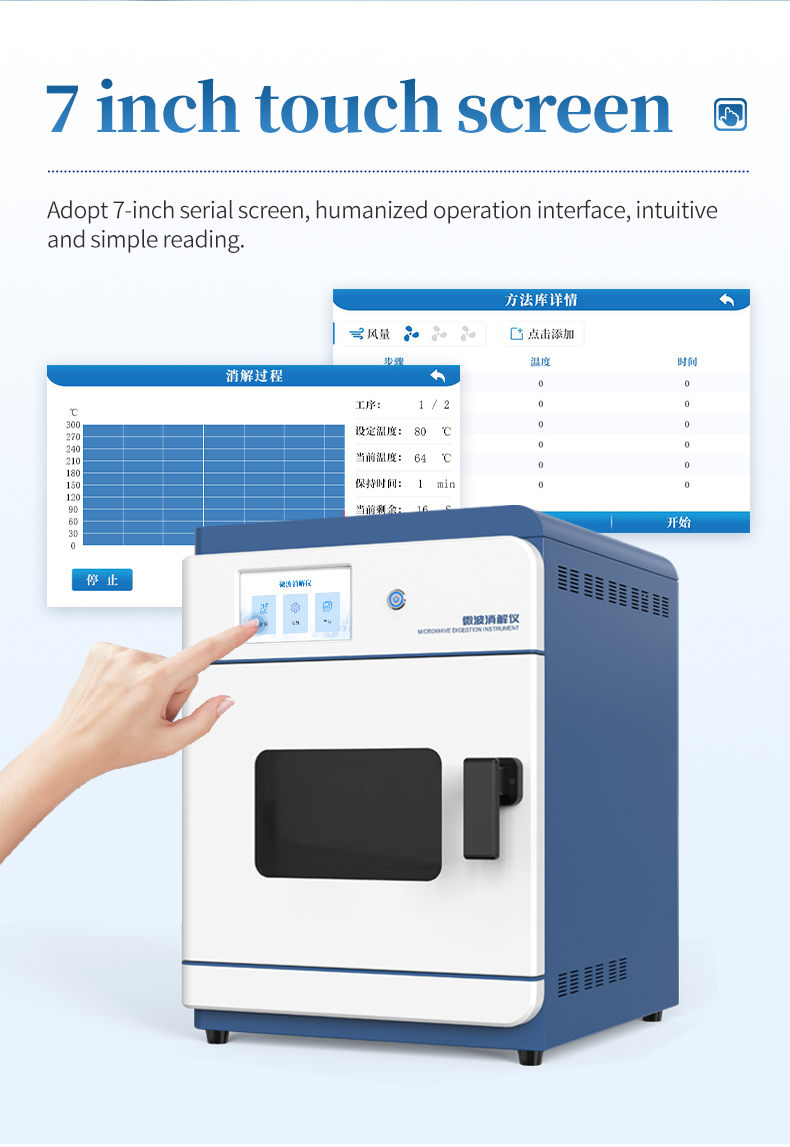

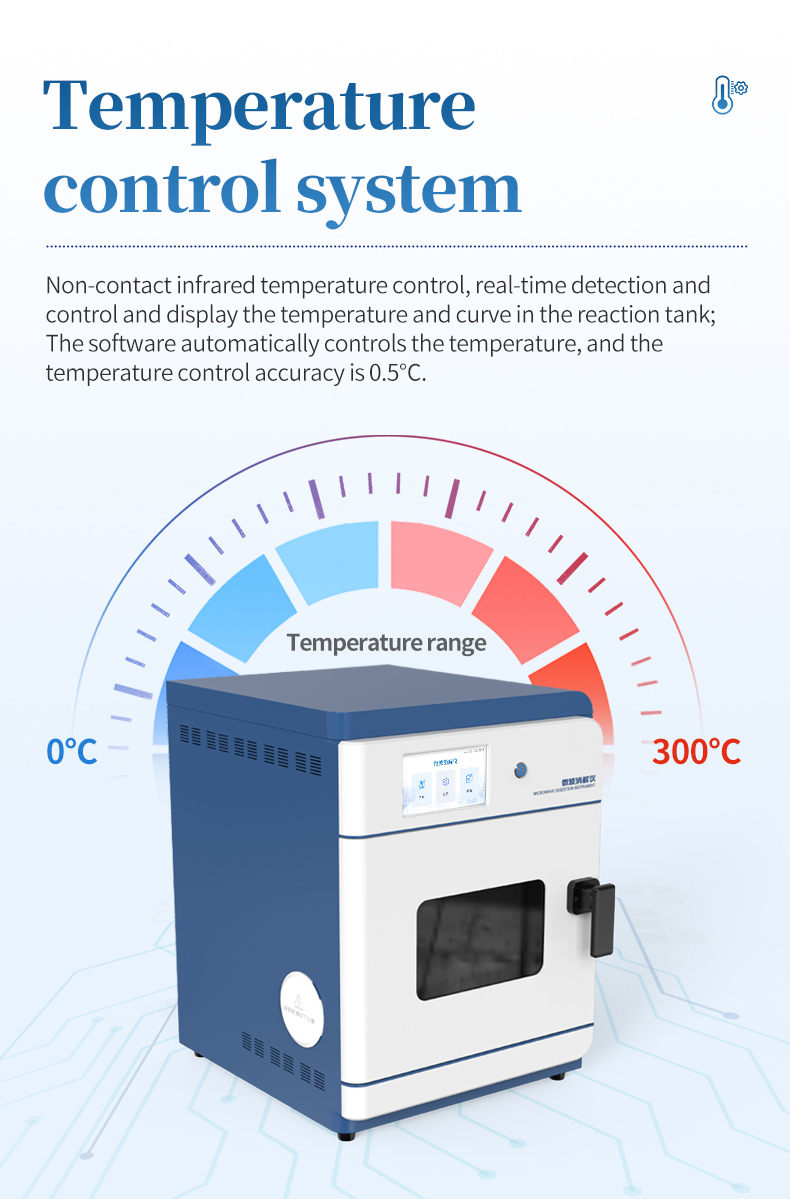

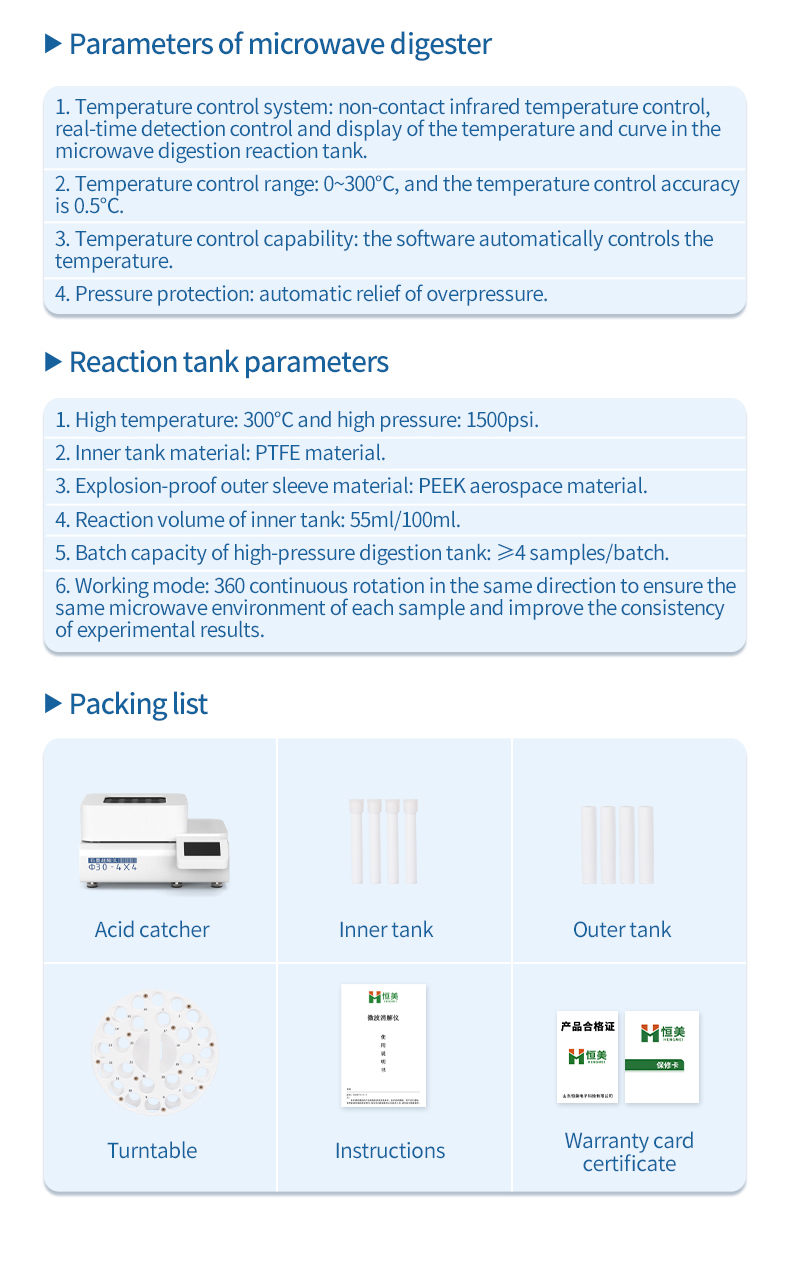

Temperature control system: non-contact infrared temperature control, real-time detection and control, and display of temperature and curve inside the microwave digestion reaction tank.

Temperature control range: 0~300 ℃, temperature control accuracy ± 0.5 ℃.

Temperature control capability: The software automatically controls the temperature.

Pressure protection: Automatic release of overpressure.

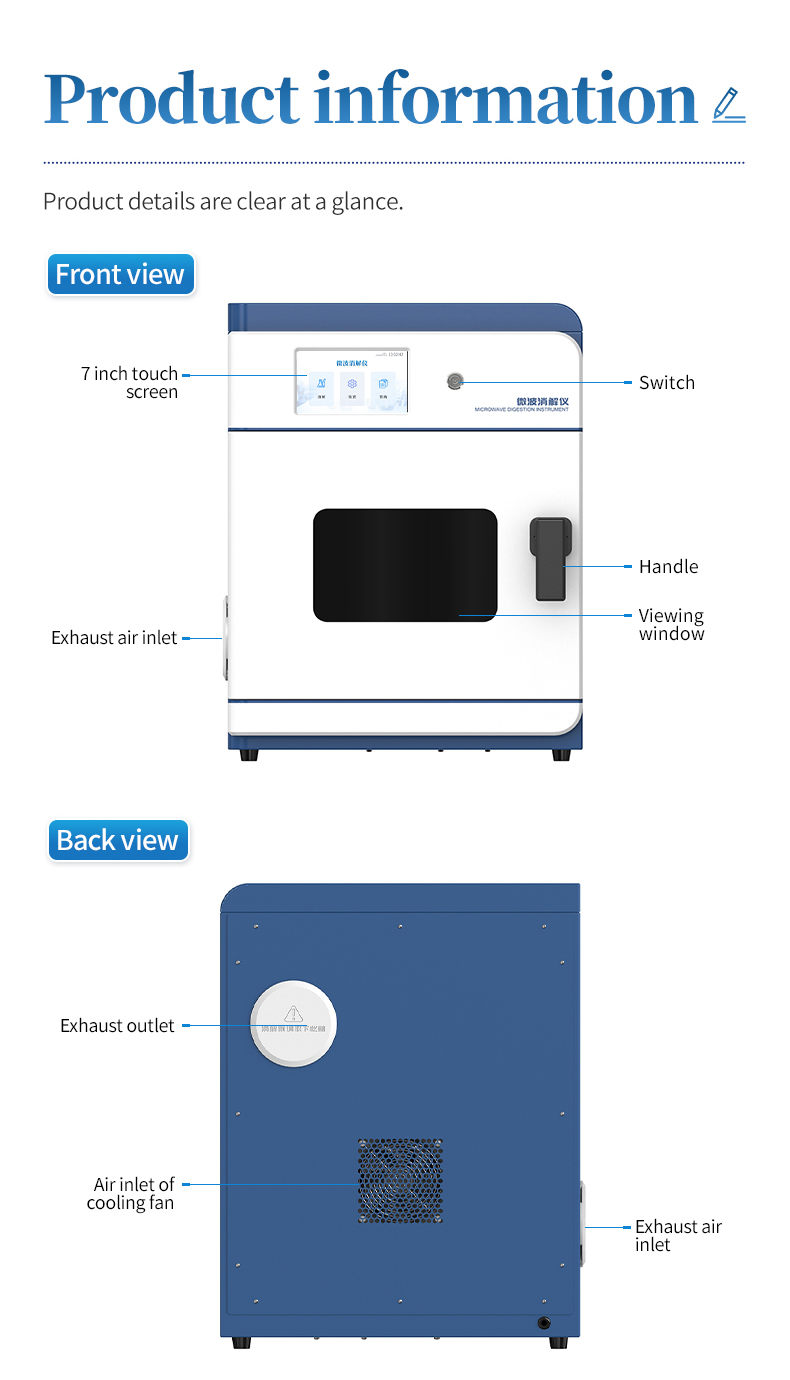

Exterior dimensions: 507 * 619.5 * 666mm (length * width * height)

Bare weight: 50kg

Reaction Tank Parameters:

High temperature: 300 ℃, high pressure 1500psi.

Inner tank material: polytetrafluoroethylene material.

Explosion proof outer sleeve material: PEEK aerospace material.

Inner tank reaction volume: 55ml.

Batch processing capacity of high-pressure digestion tank: ≥ 4 samples/batch.

Working mode: 360 ° continuous rotation in the same direction to ensure the same microwave environment for each sample and improve the consistency of experimental results.

Address of this article:https://www.kjhm.net/sysyq1/202.html- Previous: no more

- Next: Intelligent Microwave Digester

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products