Overview:

The fully automatic pesticide residue rapid detector is mainly used for quantitative analysis of pesticide residue components in samples such as vegetables and fruits. The detection system mainly includes functional modules such as project parameters, reagent position, instrument adjustment, settings, sample information, result query, initialization, and full disk cleaning. It has the characteristics of moderate analysis speed, no cross contamination, few consumables, and open reagents.

The fully automatic pesticide residue rapid detector can be widely used in product quality supervision and inspection, health and epidemic prevention, environmental protection, industrial and commercial management, vegetable wholesale markets, vegetable production bases, supermarkets, shopping malls, pesticide residue monitoring systems and other departments for the detection of pesticide residues in vegetables and fruits.

Basic principle

The fully automatic pesticide residue rapid detector is developed based on the principle of enzyme inhibition and photoelectric colorimetry. Under certain conditions, organophosphorus and carbamate pesticides have an inhibitory effect on the normal function of cholinesterase, and the inhibition rate is positively correlated with the concentration of the pesticide. When a certain amount of organophosphorus pesticides or carbamate pesticides are present in the sample extract, the enzyme activity is inhibited and the absorbance becomes higher. According to the change rate, the residual amount of pesticide in the sample can be determined.

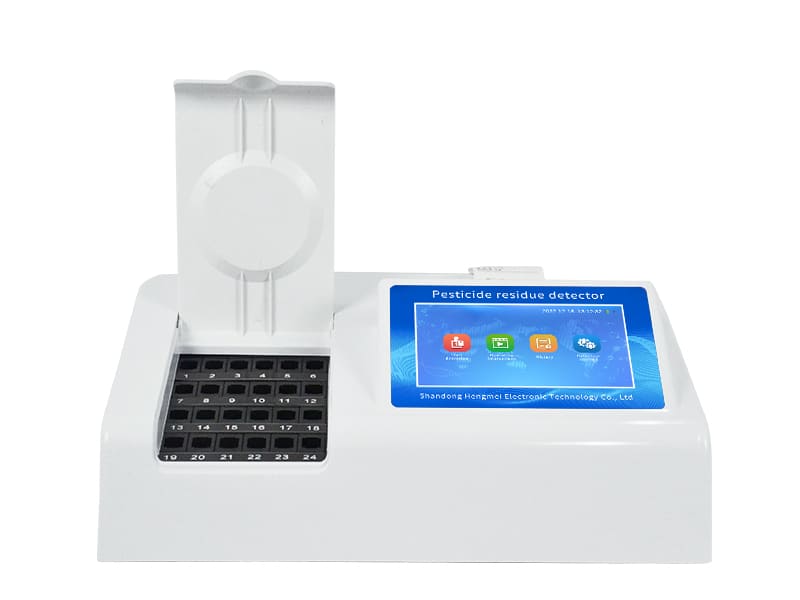

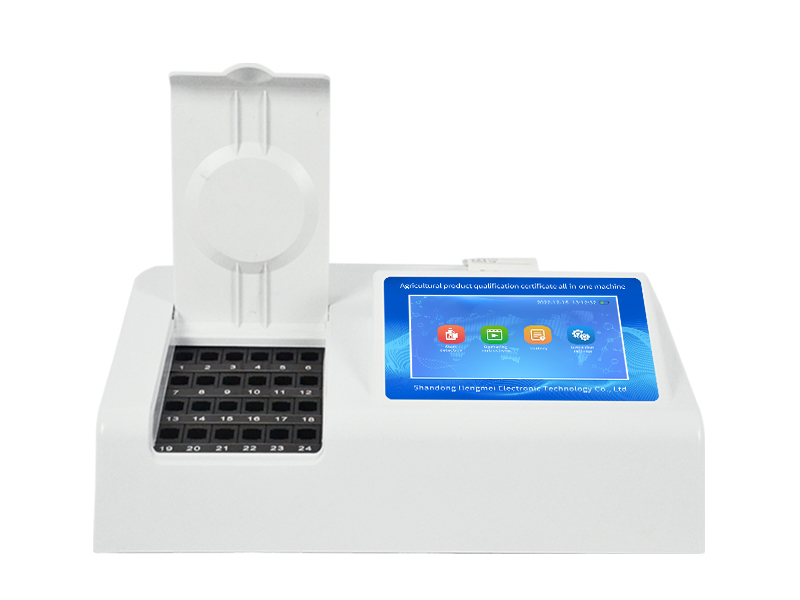

The main structure of the instrument host is as follows:

Display screen: 7-inch touch screen

Detection plate: 40-channel detection plate, cuvette capacity 500uL, detection plate has a 37℃ constant temperature system

Printer: thermal printer

Sample addition system: including motion motor and pipeline, etc.

Function introduction

1. Humanized interface, simple operation

2. Automatic blank calibration.

3. Sample addition needle liquid level sensing to avoid cross contamination.

4. Automatic cleaning of cuvette, reusable

Technical parameters

Instrument type: discrete

Analysis method: enzyme inhibition method

Measurement wavelength: 410nm

Light source: monochromatic cold light source

Sample position: 40, all subsequent processing is automated after the sample is placed.

Reaction position: 40 cuvettes made of special materials, the machine automatically adds samples, reagents, etc. to the reaction cup.

Reaction cup temperature: 37±0.1℃, the machine has a constant temperature function.

Reaction cycle: 42 seconds/each item

Reagent position: 4, compatible with the size of domestic brand reagents, reagents are automatically added.

Reagent needle: with liquid level detection, anti-collision safety protection function

Software: can be connected to the host computer, the whole machine comes with a workstation (can be operated independently), can be connected to the network for uploading

Printing: a variety of printing formats can be selected at will, the machine has a built-in thermal printer.

Power supply: AC 220V, 50Hz, 102W

Weight: about 13KG

Volume: 428mm*305mm*380m

Software: can generate upload files: upload the selected sample test results to the save path.

- Previous: Fully automatic pesticide residue detector

- Next: no more

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products