I. Overview

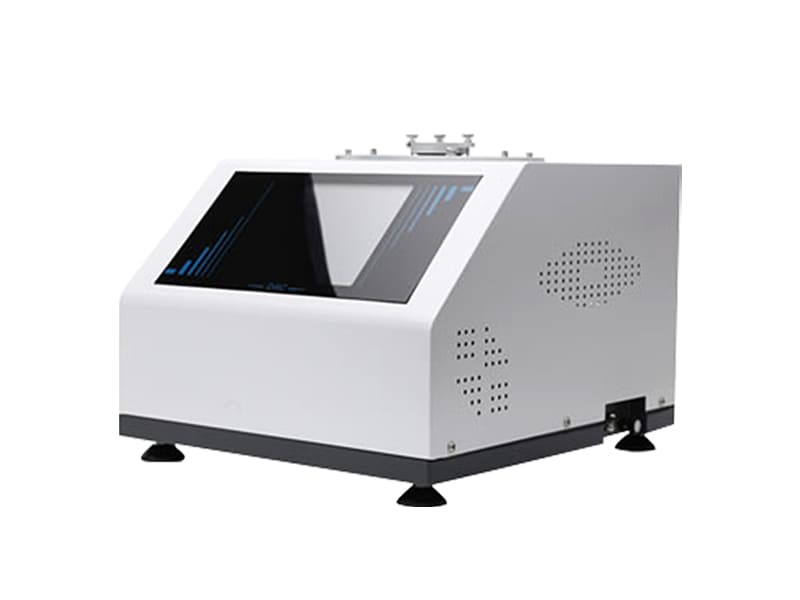

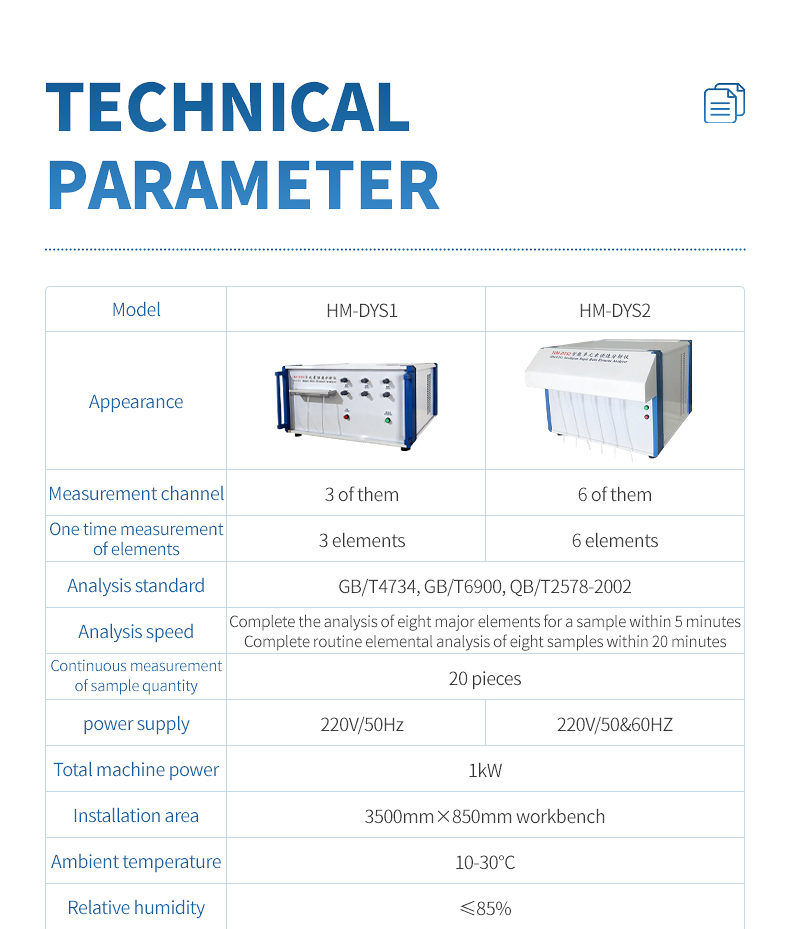

The DYS2 Refractory Multi-Element Analyzer features an improved and enlarged automatic liquid sampling device. Significant improvements have also been made to the analytical software and supporting chemical analysis procedures. Sample weighing and liquid volume have increased threefold, resulting in a substantial reduction in relative analytical error, making it a next-generation, highly ideal testing instrument. Utilizing the latest sensors and microcomputer technology, sampling sensitivity and photoelectric data resolution have been enhanced, greatly improving the accuracy of experimental data. This analyzer boasts a higher degree of automation and user-friendly design. Combined with newly developed multi-functional analytical software and incorporating our company's anti-interference technology, all adjustment functions are software-based, including automatic zeroing and automatic linear correction. The instrument's stability has been greatly improved, allowing for wide-range, accurate, and rapid analysis of more than twenty elements without complex operations. Measurement accuracy is higher, and reliability is superior. It has significant advantages in the field of silicate system analysis, and is particularly suitable for quantitative analysis in industries such as ceramics, refractory materials, glass, cement, and inorganic non-metallic minerals. This product is widely used in universities, research institutes, and factories, and has been sold throughout China and to Southeast Asia, the Middle East, Africa, Taiwan, and other countries and regions, achieving excellent results. II. Main Technical Parameters

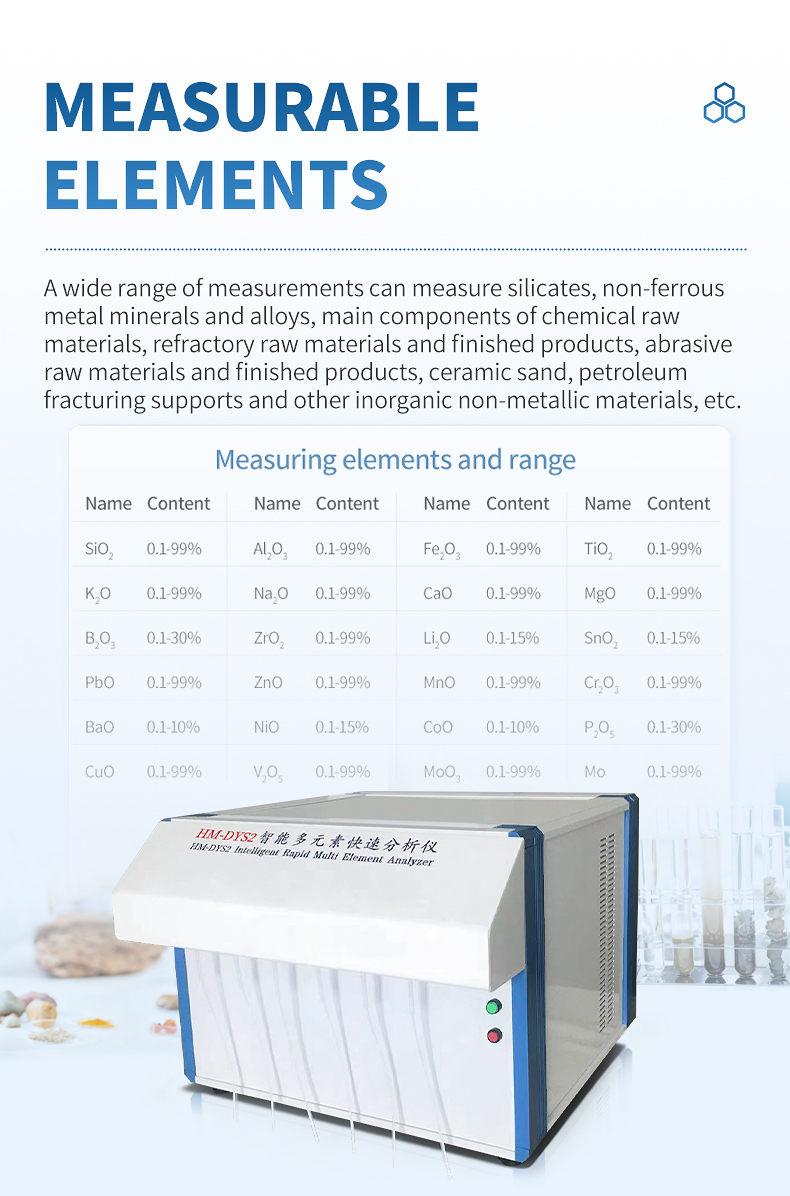

II. Measurable Elements

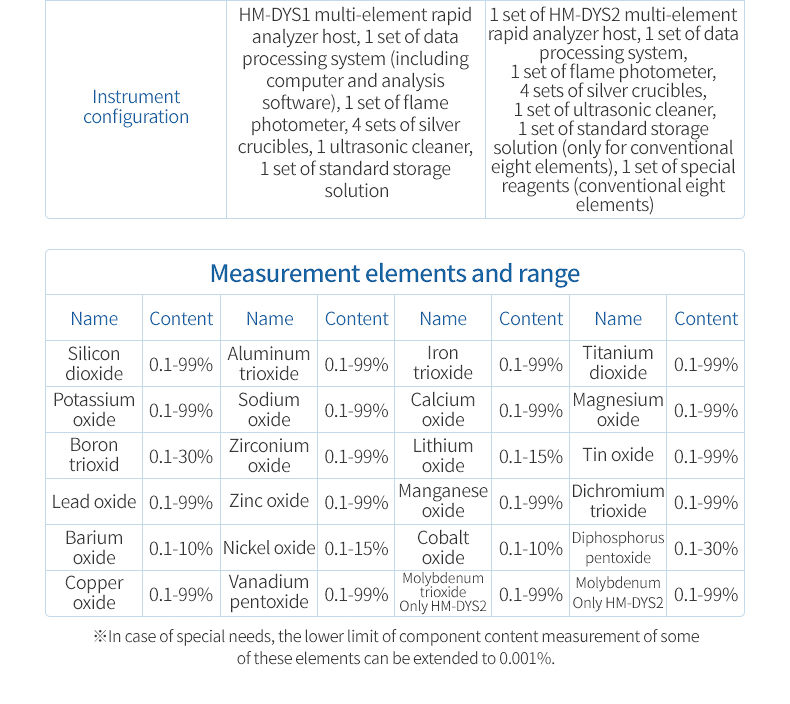

1. Measurable elements

Name | Content | Name | Content | Name | Content | Name | Content |

Silicon dioxide | 0.1-99% | Aluminum oxide | 0.1-99% | Ferric oxide | 0.1-99% | Titanium dioxide | 0.1-99% |

Potassium oxide | 0.1-99% | Sodium oxide | 0.1-99% | Calcium oxide | 0.1-99% | Magnesium oxide | 0.1-99% |

Boron trioxide | 0.1-30% | Zirconium oxide | 0.1-99% | Lithium oxide | 0.1-1 5% | Tin oxide | 0.1-99% |

Lead oxide | 0.1-99% | Zinc oxide | 0.1-99% | Manganese oxide | 0.1-99% | Chromium trioxide | 0.1-99% |

Barium oxide | 0.1-10% | Nickel oxide | 0.1-15% | Cobalt oxide | 0.1-10% | Phosphorus pentoxide | 0.1-30% |

Copper oxide | 0.1-99% | Vanadium pentoxide | 0.1-99% | Molybdenum trioxide | 0.1-99% | Molybdenum | 0.1-99% |

For special needs, the lower limit of measurement for some elemental components can be extended to 0.001%.

2. Types of materials measured

Silicates: Ceramic raw materials (including glazes) and finished products, refractory raw materials and finished products, glass raw materials (including microcrystalline glass) and finished products, main raw materials and finished products of cement, and other inorganic non-metallic materials, etc.

Non-ferrous metal minerals and alloys, main components of chemical raw materials, chromium salt products, V2O5 products, MnO products, NiO products, titanium dioxide, phosphates, cobalt oxide, zinc oxide, boric acid, borax, barium carbonate, water glass, sodium humate, lead oxide, iron oxide, nickel-cobalt-copper alloys, etc.

Refractory raw materials and finished products, abrasive raw materials and finished products, ceramsite sand, oil fracturing proppant, and other inorganic non-metallic materials, etc.

White fused alumina, sub-white fused alumina, fused alumina, tabular fused alumina, zirconium fused alumina, alumina powder, metallic aluminum powder, metallic silicon powder, silicon carbide, α-alumina, brown fused alumina, bauxite, fused alumina, andalusite, olivine, talc, dolomite, wollastonite, cordierite, mullite, zirconium mullite, magnesium aluminum spinel, limestone, calcite, potassium sodium feldspar, diopside, spodumene, lithium feldspar, fluorite, quartz sand, quartz powder, silica fume, white silica fume, perlite, magnesia-chrome bricks, high alumina cement, aluminate cement, refractory mortar, silicate cement, zircon sand (powder), fly ash, zirconium silicate, zirconium oxide, magnesia, magnesia powder, manganese powder, nepheline, kyanite, sillimanite, pyrophyllite, aluminum hydroxide, calcium aluminate, various clays, white clay, kaolin, bentonite, sepiolite, sericite, basalt, slag, briquettes, rod powder, etc. 3. Measurement Channels: 6

4. Stability: Measurement reading change within ±1 digit in 5 minutes.

5. Analytical Accuracy: The analytical accuracy for each element meets or exceeds the permissible error specified in the relevant national standard analytical methods (GB/T4734, GB/T6900, QB/T2578-2002).

6. Analytical Speed: Complete eight-element analysis of one sample within 5 minutes; complete routine elemental analysis of eight samples within 20 minutes.

7. Number of samples to be measured continuously: 20

8. Instrument operating conditions

Power supply: 220V, 50&60HZ

Total power: 1KW

Installation area: 3500x850mm worktable

Ambient temperature: 10-30℃

Relative humidity: ≤85%

III. Instrument configuration

1. HM-DYS2 Refractory Material Multi-Element Analyzer Main Unit: One unit;

2. Data processing system: One set;

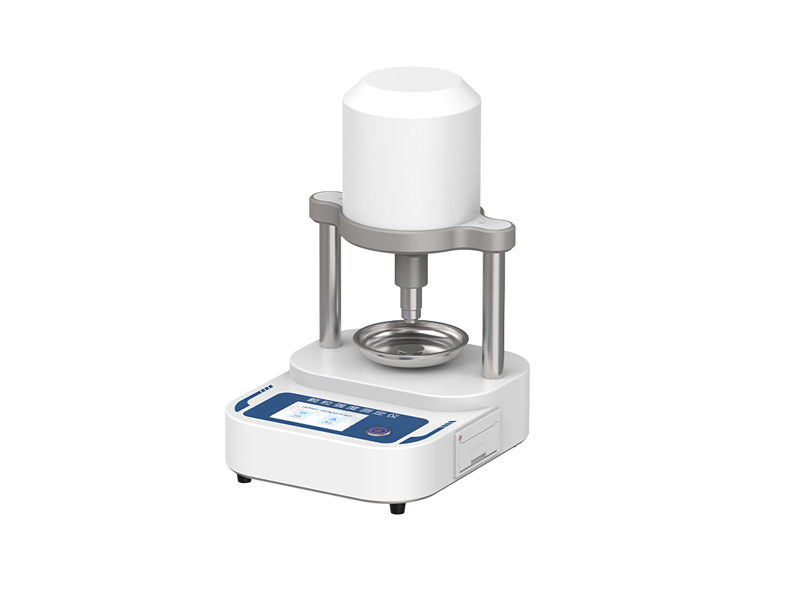

3. Flame photometer: One set;

4. Silver crucibles: Four sets;

5. Ultrasonic cleaner: One unit;

6. Standard stock solution: One set (for conventional eight elements only);

7. DHF-88 special reagent (for conventional eight elements): One set

Address of this article:https://www.kjhm.net/mera/799.html- Previous: Intelligent Multi-Element Rapid Analyzer

- Next: no more

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products