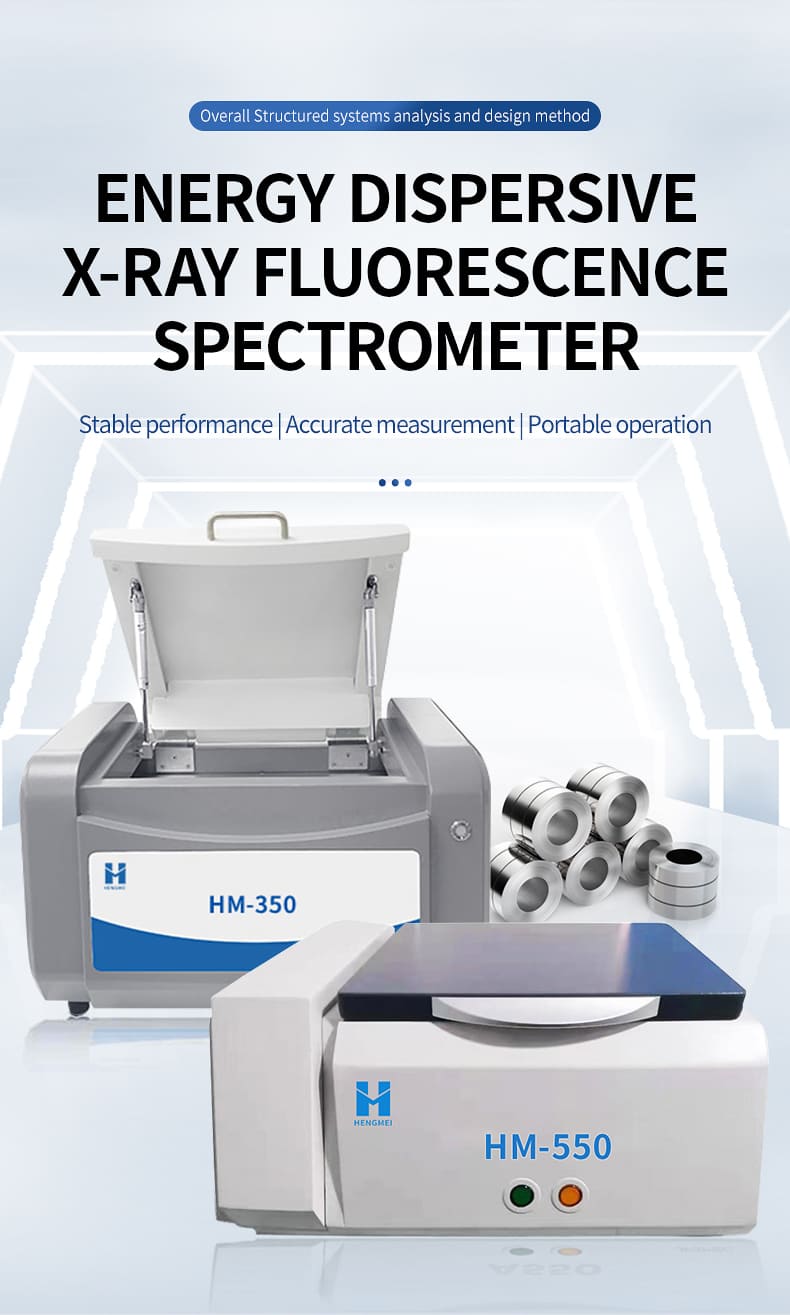

Introduction to product name and model specifications:

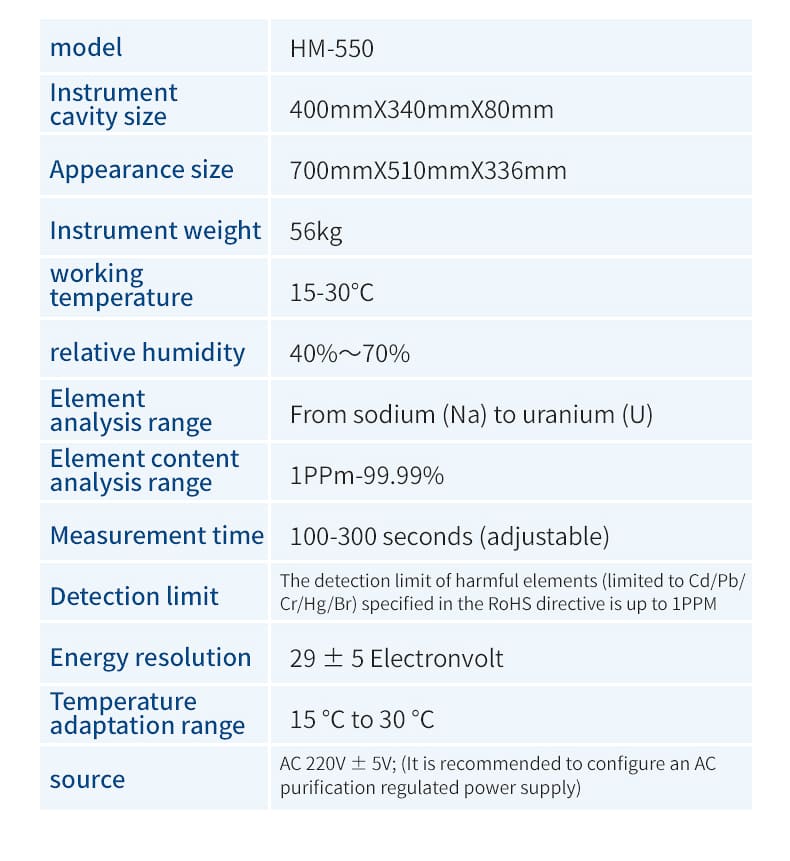

1.1 Product name and model:

Energy dispersive X-ray fluorescence spectrometer - HM-350 model

1.2 Manufacturer: Hengmei Zhizao

1.3 Instrument specifications

Instrument chamber size 439mmX300mmX150mm

Instrument appearance size 550mm x 410mm x 320mm

Instrument weight 45kg

1.4 Working conditions:

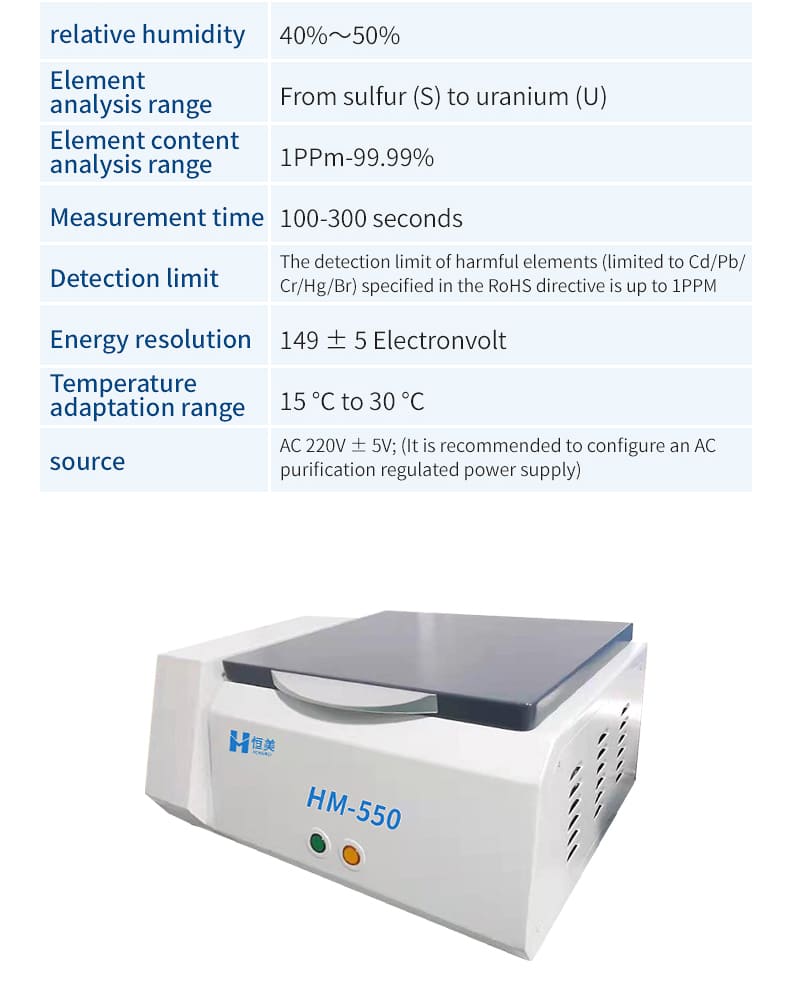

Operating temperature: 15-30 ℃

Relative humidity: 40% to 50%

Power supply: AC: 220V ± 5V

1.5 Technical performance and indicators:

1.5.1 The range of elemental analysis ranges from sulfur (S) to uranium (U);

1.5.2 The range of element content analysis is from 1 PPm to 99.99%;

1.5.3 Measurement time: 100-300 seconds;

1.5.4 The detection limit of harmful elements specified in the RoHS directive (limited to Cd/Pb/Cr/Hg/Br) is as high as 1PPM;

1.5.5 The energy resolution is 149 ± 5 electron volts;

1.5.6 The temperature adaptation range is 15 ℃ to 30 ℃;

1.5.7 Power supply: AC 220V ± 5V; (It is recommended to configure an AC purification stabilized power supply.)

1.6. Product features

1.6.1 HM-350 is a product specifically designed for environmental directives such as RoHS and EN71.

1.6.2 Breaking away from the traditional straight design of instruments and adopting a streamlined integrated design, the instrument is fashionable and elegant.

1.6.3 Adopting a new type of Si pin detector from the United States, which is electrically cooled instead of liquid nitrogen cooling, it has a small volume, accurate data analysis, and low maintenance cost.

1.6.4 Adopting a self-developed SES signal processing system, effectively improving the sensitivity of measurement and making measurement more efficient.

1.6.5 One click automatic testing, simpler to use, more convenient, and more user-friendly.

1.6.6 Seven types of optical path correction and collimation systems, automatically switching according to different samples.

1.6.7 Multiple radiation leakage prevention design, radiation protection level belongs to the Highest of similar products.

1.6.8 Advanced integrated heat dissipation design greatly improves the overall heat dissipation performance of the machine, ensuring the safe operation of core components.

1.6.9 Unique movement temperature control technology ensures the safe and reliable operation of the X-ray source, effectively prolongs its service life, and reduces usage costs.

1.6.10 Multiple instrument accessory protection system, which can be fully monitored through software, making the instrument work more stable and safe.

1.6.11 RoHS dedicated testing software with standard window design, user-friendly interface, and easy operation.

1.6.12 This machine adopts a USB2.0 interface, effectively ensuring accurate, high-speed, and effective data transmission.

Main hardware configuration of the instrument

2.1 Si pin electrically cooled semiconductor detector:

2.1.1 Si pin electrically cooled semiconductor detector; Resolution: 149 ± 5 electron volts

2.1.2 Amplification circuit module: detecting X-ray characteristics of the sample; Further amplify the information collected by the detection.

2.2 X-ray excitation device:

2.2.1 Filament current: Filament current output MAX: 1mA;

2.2.2. Belongs to semi loss type components, 50W, air-cooled.

2.3 High voltage launch device:

2.3.1 Voltage and voltage output MAX: 50KV;

2.3.2. Voltage output MIN: 5KV, controllable adjustment

2.3.3. Equipped with voltage overload protection

2.4 Multi channel analyzer:

2.4.1 Convert the collected analog signals into digital signals and provide the processing results to the upper computer software.

2.4.2. Maximum number of tracks: 4096;

2.4.3 Including signal enhancement processing

2.5 Optical path filtering module

2.5.1 Reduce interference during X-ray transmission and ensure accurate signal reception by the detector.

2.5.2 Integrate the collimator with the filter;

2.6 Collimator automatic switching module

2.6.1 Up to 8 options, with calibers of 8 #, 6 #, 4 #, 3 #, 2 #, 1 #, 0.5 #, 0.2 #.

2.7 Filter automatic switching module

2.7.1 Free selection and switching of six types of filters.

2.8 Automatic selection module for working curves

2.8.1 Automatic selection of working curves, abandoning manual selection, avoiding human operational errors, and integrating automation and intelligence

Perform more perfectly, making the operation more humane and convenient.

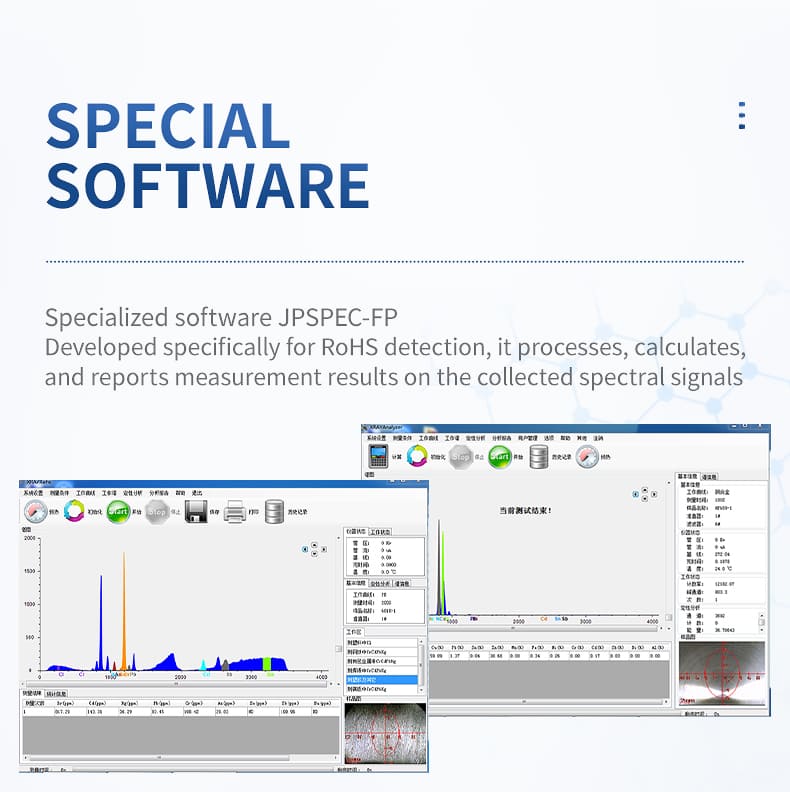

Specialized software JPSPEC-FP

3.1.1 Software Introduction

Specially developed for RoHS detection, it processes, calculates, and reports measurement results on the collected spectral signals.

3.1.2 Function Introduction

※ Specially respond to the testing of six elements Cd, Pb, Hg, Br, Cr, Cl involved in the six substances specified in the EU RoHS Directive, with a measurement time of 100-300 seconds

※ The operation interface is simple and intuitive, easy to use, and does not require professional operation

※ Suitable calibration curves can be automatically selected, making measurement more convenient and accurate.

※ Automatic switching between Chinese and English interfaces, with third-party language customization function

※ Automatically calibrate the instrument.

※ Equipped with qualitative analysis of sample materials to prevent manual users from selecting incorrect curves

Print multiple report formats.

※ Can display multiple spectrograms simultaneously

The unique movement temperature monitoring technology ensures the safe and reliable operation of the X-ray source, effectively prolongs its service life, and reduces usage costs.

Sample configuration

Standard samples are used to create working curves

4.1 Sample chamber

Open sample chamber

4.2 Standard sample

EU standard E60K

Pure silver sample

Product warranty and after-sales service

5.1 Provide free training to customer operators.

5.2 Installation, debugging, acceptance, training, and technical services are all free on-site training for operators at the user's site.

5.3 Normal use, confirmed by the technical personnel of our company's after-sales service department that the malfunction is caused by process or material defects, and has not been disassembled or repaired. The instrument is guaranteed for one year from the date of acceptance.

5.4 Lifetime maintenance of the product. (Customers must have filled out detailed and authentic valid purchase vouchers, invoices, and warranty cards, etc.)

5.5 Provide free software upgrades;

5.6 Provide effective technical services, respond within 2 hours upon receiving user fault information, and if necessary, send personnel to repair and troubleshoot within 48 hours.

- Previous: RoHS detector

- Next: Handheld X-ray fluorescence spectrometer

Current

Location:

Current

Location:

+86 17853698681

+86 17853698681 WhatsApp

WhatsApp Product Details

Product Details Related Products

Related Products